In the fast-evolving landscape of quality training for the aerospace industry, the sector faces many challenges, from ensuring precision in complex production processes to maintaining the highest safety standards. Central to navigating these challenges is the role of qualified production staff, whose expertise becomes the linchpin of operational success.

As we delve into the aerospace manufacturing training paradigm, it’s evident that traditional methods are significantly transforming. The integration of cutting-edge technologies, particularly Augmented Reality (AR), Mixed Reality (MR) and Virtual Reality (VR), is not just a trend but a revolutionary step in enhancing the skills and capabilities of production personnel.

The Challenges in Aviation Production Industry

Navigating Complexities

Aviation maintenance, a field defined by its precision and complexity, faces significant challenges. The industry demands exacting standards, where even minor errors can impact safety and functionality. This high-stakes environment underscores the importance of aviation maintenance training, ensuring a workforce capable of meeting these rigorous demands.

Balancing Quality and Efficiency

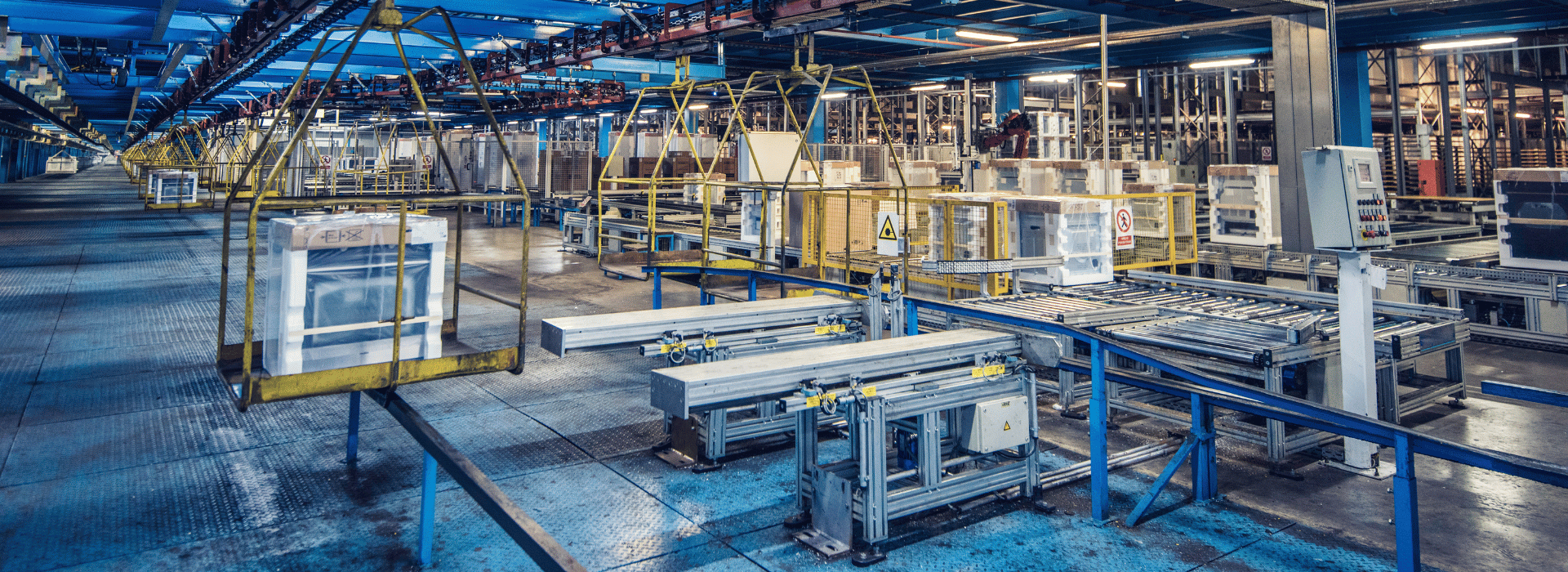

Maintaining quality while optimizing efficiency is pivotal in aviation maintenance. The industry’s success hinges on a workforce that excels in technical proficiency and is adept with advanced manufacturing practices, including factory automation. This necessitates quality training, particularly in areas like AR in aerospace manufacturing training, to equip staff for these critical roles.

The Crucial Role of Qualified Production Staff

Ensuring Industry Excellence

The aviation maintenance industry critically depends on the expertise of its production staff. These professionals are essential for achieving the precision and safety standards the industry demands. Quality training for the aerospace industry is vital, directly influencing the reliability and performance of aerospace products.

Driving Industry Success

The proficiency of production staff is intrinsically linked to the aerospace industry’s overall success. Skilled personnel adept at handling advanced technologies and complex manufacturing processes are indispensable.

As the industry gravitates towards digital solutions, including augmented reality in aviation maintenance and investing in high-quality training, it becomes crucial for future-proofing the sector.

presentation to try

Nsflow in action

Evolution of Training Methods in the Aviation Industry

From Traditional to Modern

Traditionally, aviation maintenance training focused on theoretical classroom learning and on-the-job experience. However, these methods often needed to be revised to address the complexities of modern aerospace production. As technology advanced, so did the need for more dynamic training approaches.

Embracing Technology in Training

The industry has witnessed a significant shift towards incorporating digital technologies in training. Augmented Reality (AR) and Virtual Reality (VR) have emerged as pivotal tools, offering immersive and interactive learning experiences. This evolution reflects a move towards more practical, hands-on training methods, aligning with the technological advancements and intricate manufacturing processes in aerospace production.

Integrating New Technologies in Aerospace Manufacturing Training

Innovative Training Technologies

The aerospace manufacturing sector is significantly transforming through the integration of AR and VR technologies, aligning with the trend of automation in aviation maintenance. These tools have revolutionized traditional training methods by offering immersive and interactive learning experiences. Augmented reality in aerospace enables trainees to engage with 3D models, enhancing their understanding of complex aircraft components and systems in this automated environment.

Enhancing Training Effectiveness

These technological advancements have made training more effective and aligned with modern manufacturing practices. By simulating real-world scenarios, AR and VR enable trainees to gain hands-on experience in a risk-free environment, preparing them for the challenges of contemporary aerospace manufacturing and ensuring a workforce adept at navigating the industry’s evolving technological landscape.

Integrating New Technologies in Aerospace Manufacturing Training

A New Training Paradigm

The abovementioned technologies provide immersive simulations, offering a practical and safe training environment. For example, AR in aerospace manufacturing training enables trainees to interact with 3D models of aircraft components, enhancing their understanding of complex systems beyond what conventional methods could achieve.

Elevating Skills and Proficiency

Moreover, the application of AR and VR in the learning process is transforming the skill set of aviation maintenance training staff. These technologies allow for realistic simulations of scenarios like assembly processes and maintenance tasks without the risks associated with physical components or hazardous environments. This approach improves skill acquisition and aligns with the industry’s shift towards automation in aerospace manufacturing. As a result, the workforce is better prepared for a future where digital processes predominate, ensuring agility and competence in meeting the industry’s changing demands.

AR in Aerospace Manufacturing Training

Evolution of AR in Training

Incorporating augmented reality in aviation maintenance training has evolved significantly. Initially emerging as a novel concept, AR was gradually explored for its potential to enhance training programs. Early applications were limited but set the foundation for more advanced uses. Industrial augmented reality technology has become more sophisticated, offering more realistic and interactive experiences and cutting-edge AR glasses.

Impactful Milestones in AR Adoption

The aerospace industry has witnessed several pivotal moments in adopting AR for training. These milestones demonstrate how AR has evolved from a supplementary tool to a central component in training programs within automated manufacturing environments. Its ability to provide immersive, detailed visualizations of complex aerospace components has transformed traditional training methods, making AR an indispensable asset in the industry’s training repertoire, especially as it moves towards greater automation in aerospace manufacturing.

AR-Driven Transformation in Aerospace Manufacturing Education

Revolutionizing Traditional Training Methods

Augmented Reality revolutionizes aviation maintenance training, shifting the paradigm from conventional methods to more dynamic and interactive approaches. By integrating augmented reality in training and onboarding, trainees gain an unparalleled understanding of complex aerospace components and systems through immersive 3D visualizations. This method enhances the learning experience and ensures a more profound and lasting grasp of essential manufacturing processes.

Spatial Annotations in AR

AR also introduces spatial annotations in remote support sessions, improving the learning and problem-solving process. This feature allows experts to overlay detailed information such as descriptions, attributes, and metadata directly on specific objects or areas in an AR scene. This contextual integration of information allows for a more intuitive understanding of machines or products. When the instructor highlights real-world elements, it is easier for technicians and students to connect this overlaid information with real locations on the device, streamlining the servicing or learning process.

Cultivating Advanced Skills for Modern Manufacturing

Implementing AR in training is pivotal for cultivating advanced skills required in modern quality training. It enables a more efficient and resource-effective training process, significantly reducing the time and cost associated with traditional training methods.

Moreover, AR’s capability to simulate a wide range of manufacturing scenarios equips the workforce with versatile skills, preparing them for the challenges of an increasingly automated and digitalized aerospace industry. This aligns perfectly with the industry’s focus on digital manufacturing solutions for the aviation industry, ensuring a future-ready workforce.

The New Era of AR in Aerospace Manufacturing Training

Augmented Reality integration in aviation maintenance training, exemplified by platforms like Nsflow, is revolutionizing the industry. Cultivating a future-proof factory for aviation maintenance requires embracing innovative technologies and ensuring that the workforce is equipped to meet the evolving demands of this dynamic industry.

Nsflow’s innovative features offer an advanced approach to training production workers, aligning with the modern needs of aerospace manufacturing. This platform provides a hands-on learning experience, making complex training more accessible and practical.

Industry professionals can experience the transformative potential of Nsflow firsthand with a free 14-day demo, witnessing how augmented reality can elevate training standards.