Maintenance optimization

Tame the potential of AR-powered maintenance and service operations.

Maintenance personnel support

Equip your maintenance teams with a comprehensive AR platform.

Get to know more

Ensuring safety

Proper and regular maintenance is essential to keep the working environment safe. Shortcomings in this area can result in hazardous situations and accidents.

Reducing downtimes

Maintenance professionals ensure all equipment and machinery are operational and available 100% of the time required by the enterprise.

Skills and experience

Technicians and engineers put their expertise to great use when ensuring the best condition of machinery for the company’s operations benefit.

Maintenance challenges

Maintenance consists of high-risk operations, working under the pressure of time and a multitude of tasks, followed by combining expert knowledge with proficiency in various systems and methodologies.

Unplanned maintenance

Handling unexpected downtimes disrupts industrial processes, taking up personnel time. The problem occurs due to flawed or no prediction of upcoming service work in the facility.

Costs

Routine maintenance generates fixed expenses. Over time, conservation costs grow, as on-site machinery ages and no longer functions flawlessly. The introduction of new, more advanced equipment will also entail higher costs.

Loss of talents

Experienced personnel leaves, taking their expertise with them. Training and onboarding new staff is timely, costly, and requires modern methods to keep up with the dynamic changes.

Remote processes

No direct access to expert knowledge while working offsite can suspend operations, affecting the overall productivity. Maintenance requires a real-time, direct response to occurring issues.

What troubles your company?

We will be happy to discuss your needs and possible solutions.

The solution

Maintenance operations can be easily optimized by using a tailored AR solution:

A wide choice of features for maintenance personnel

Virtual models

The AR platform enables to use 3D models and digital twins to depict the serviced machinery. Predictive maintenance experts can check under the hood without halting the machine’s operations.

Data management

Data generated during maintenance operations can be automatically saved in convenient PDF reports and protocols. Information can be processed, analyzed, and visualized for future use.

Integration with SCADA and IIOT systems

Performance and accuracy of maintenance processes are improved by integrating internally-used systems, streamlining specialists’ work.

Digital twins

Virtual representations of on-site machinery allow for looking under the hood. Results? Improved recognition and prediction of possible malfunctions, without the need of halting operations.

AR benefits for maintenance specialists

Error reduction

The watchful eye of AR assists technicians in carrying out maintenance duties. Premade workflows guide users through step-by-step instructions, leaving no room for error.

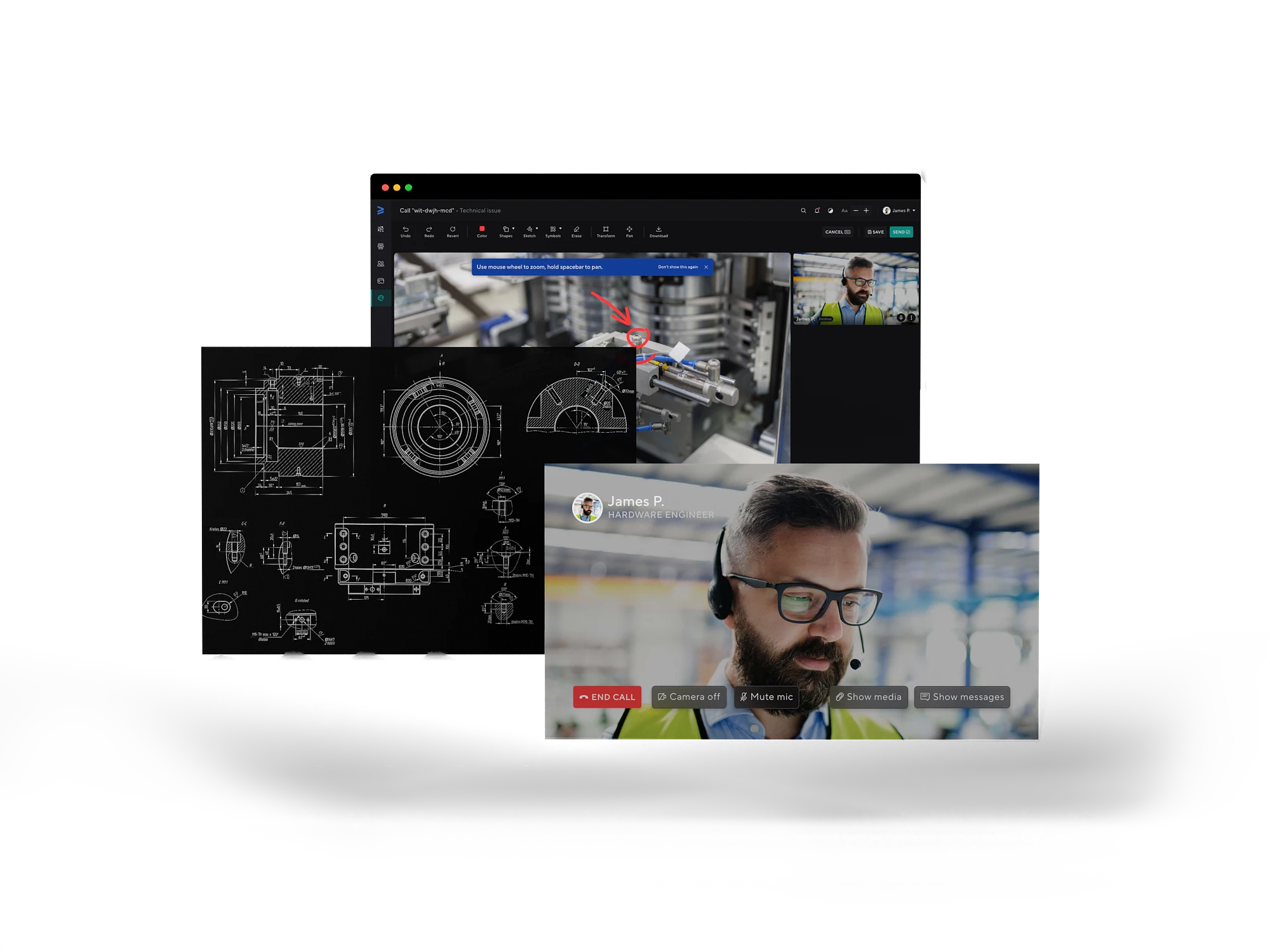

Real-time assistance

Should an unusual issue occur, on-site personnel won’t have to resolve it on their own. Direct contact with remote experts allows for handling even the most complex maintenance problems.

Increased safety

Wearable AR devices allow maintenance personnel to work hands-free and operate the platform using voice commands and gestures. Technicians can fully focus on their duties, reducing the risk of accidents.

Knowledge retention

The AR platform provides insights into the correctness of executed exercises and participants’ progress. Reports are generated automatically and allow for convenient analysis and tracking.

Learn more about our solution

Get a free 14-day trial*

*AR devices included, no risk and cost involved