Digitalize production processes in the machinery industry

Take advantage of augmented reality in daily operations to respond to the most significant challenges of the machine industry

The machinery industry

Machinery companies produce equipment without which organizations from other sectors wouldn’t be able to operate. The newest technologies help them in their daily endeavors.

Challenges

Production effectiveness

Improving efficiency is necessary to achieve and maintain a strong market position. Industry 4.0 tools help to reduce errors and allow to perform essential procedures remotely.

Employee churn

Even though a lot of processes become automated, machinery manufacturing still relies heavily on the workforce. Effective training and tasks performed remotely help to overcome the problem.

Human error risk

Machinery production requires great precision and focus. Thus the process is error-prone. Technology can help you detect problems before any costly, project-threatening mistakes are made.

Rising costs

The prices of raw materials, such as steel, are skyrocketing. To maintain the market position and price competitiveness, manufacturers have to boost their production processes

Get to know more

The solution

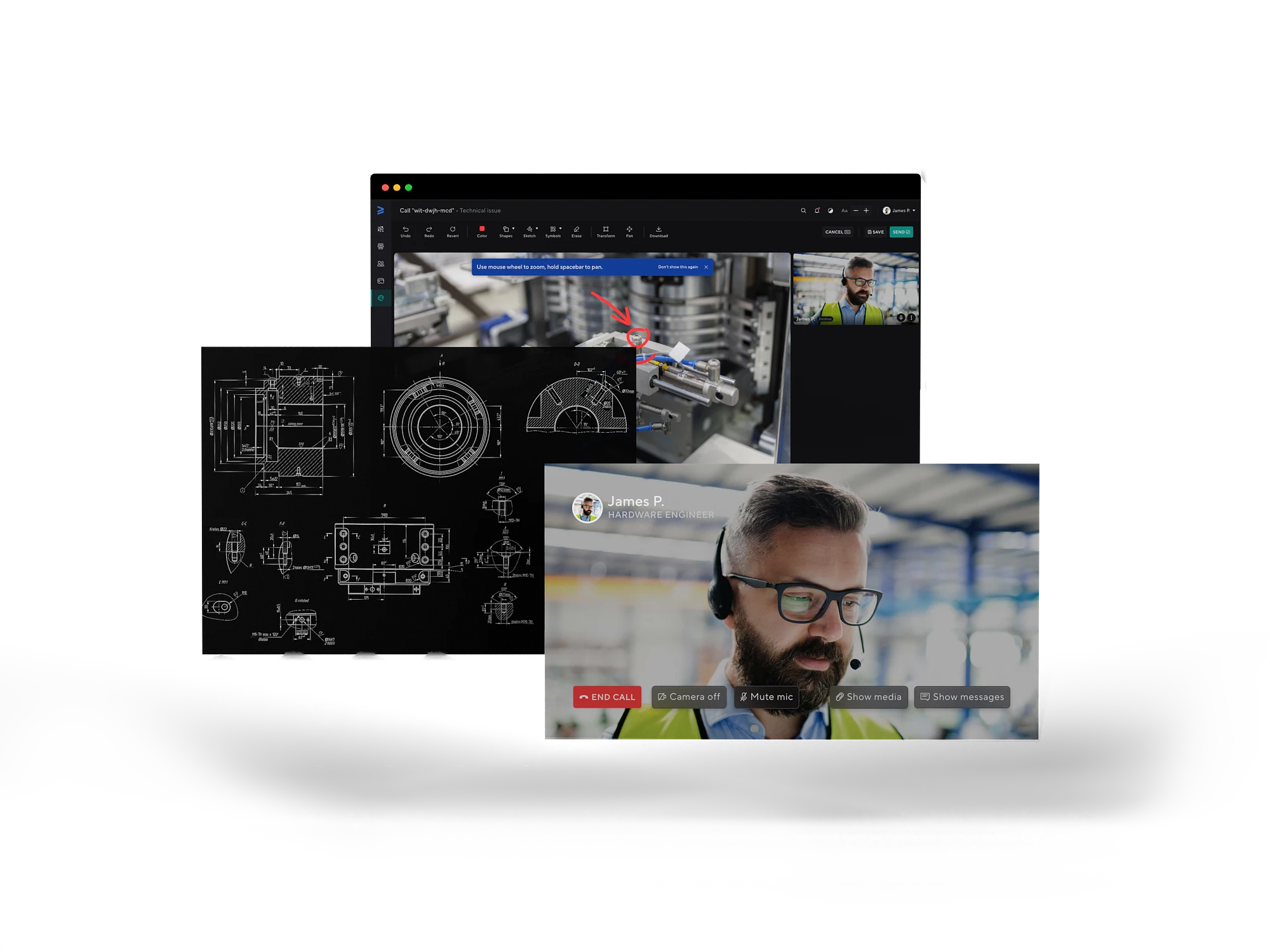

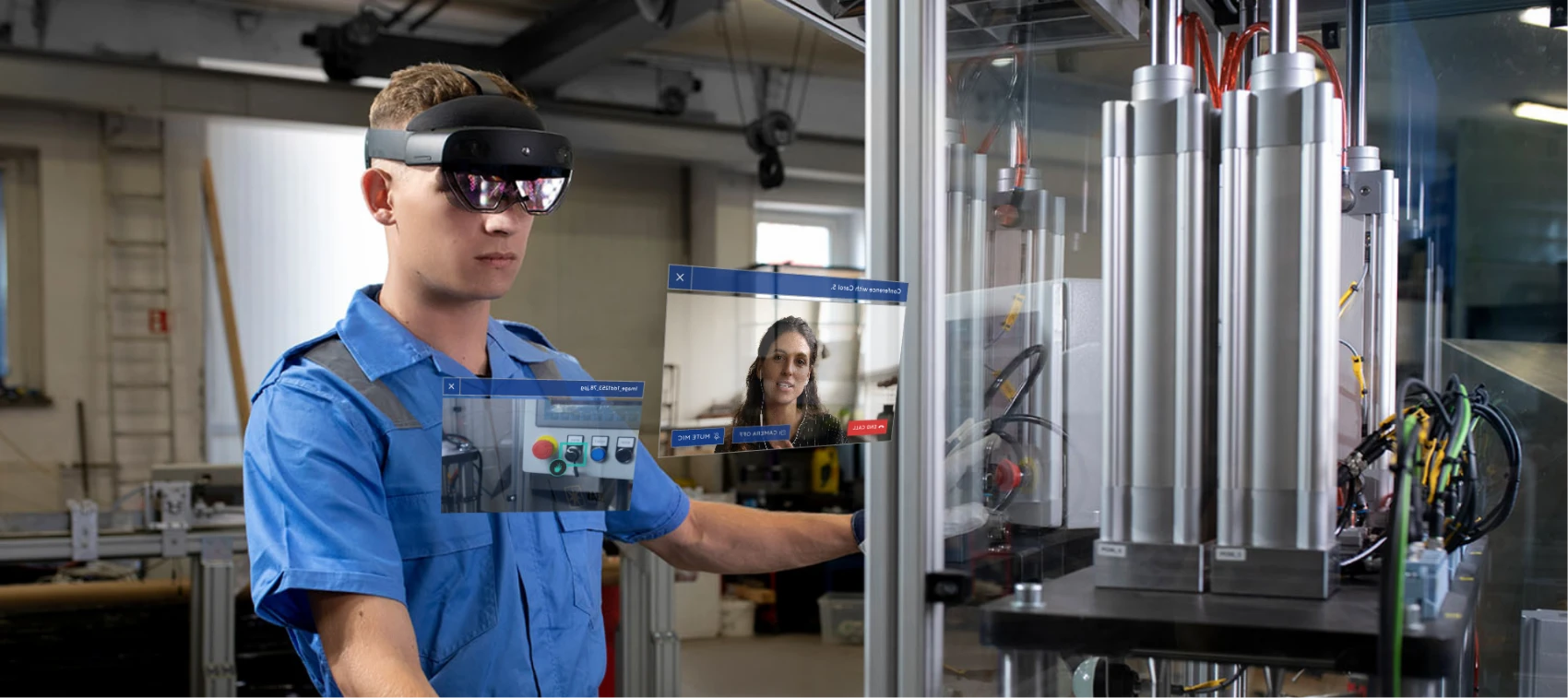

The answer to the machine industry challenges is a digital platform powered by AR, with two built-in modules

The key features that will boost effectiveness and help you reduce risk

Remote FAT

Perform factory acceptance tests remotely thanks to augmented reality. Let your customers verify machinery quality and functions before it leaves your plant. No in-person visits needed.

Machinery maintenance

Carry out machinery maintenance remotely, assisting your clients’ technicians via AR glasses. This way, your expert can perform multiple procedures a day without wasting time traveling.

Training automation

Alleviate the problem of employee churn with AR training that involves minimal trainer involvement. The system verifies whether the tasks are completed correctly to avoid human error risk.

Digital twins

Use digital copies of your machinery to plan it in your or your client’s machinery parks. Organize training sessions with virtual machines before your new employees operate the real ones.

Benefits of Nsflow

Cost effectiveness

Augmented reality in the machine industry allows you to cut costs of staff onboarding, training, expert assistance, and human errors. Perform tasks remotely for even more savings.

Minimized risk

By guiding your employees step by step and verifying task completion, the system keeps guard over faultless machinery production. It also helps to avoid downtimes at your plant.

Business continuity

Secure your business going paperless, automating training and production processes, and retaining knowledge for the next generations of employees. Introduce procedures preparing you for the unexpected.

Improved quality

Instantly accessible documentation, standardized employee knowledge, work checklists, error notification, and remote procedures help you to improve the quality of machinery you deliver.

Learn more about our solution

Get a 14-day

FREE TRIAL

AR devices included, no risk and no cost involved.

See more use Cases

Nsflow solutions can be adopted in a variety of industrial scenarios to improve your business processes.

Industrial onboarding

Get your employees ready to work with step-by-step AR training, with minimal instructor engagement.

Remote FAT

Check equipment and machinery functionality and quality before they leave the production line – remotely.

Remote Support

Eliminate the distance barrier between your technicians working in the field and experts.