Improving processes in the mining industry with augmented reality

The potential of AR supports daily operations carried out by mining enterprises worldwide

The mining industry

The sector is responsible for unearthing the wealth of resources like oil, gas, coal, metals, and industrial minerals, providing fuel and raw materials that drive the economy.

Challenges

Staff shortages

The ongoing process automation doesn’t lessen the importance of the workforce in tasks impossible to carry out without human expertise. The retirement of skilled employees and the influx of new staff require efficient training processes.

Occupational risks

Hazards of mining operations are associated with operating in dangerous environments near heavy machinery, and cover accidents, explosions, and exposure to noise, toxic gasses, and temperature.

Digitalization

Without a smooth transition to digital processes, the sector will stay behind. Catching up with other market fields in times of Industry 4.0 calls for changes in how internal data, resource management, and training are carried out.

Operational continuity

Elimination of downtimes is crucial for the sector that powers the global economy. Each interruption comes with an avalanche of delays and unnecessary costs.

Get to know more

The solution - augmented reality in mining

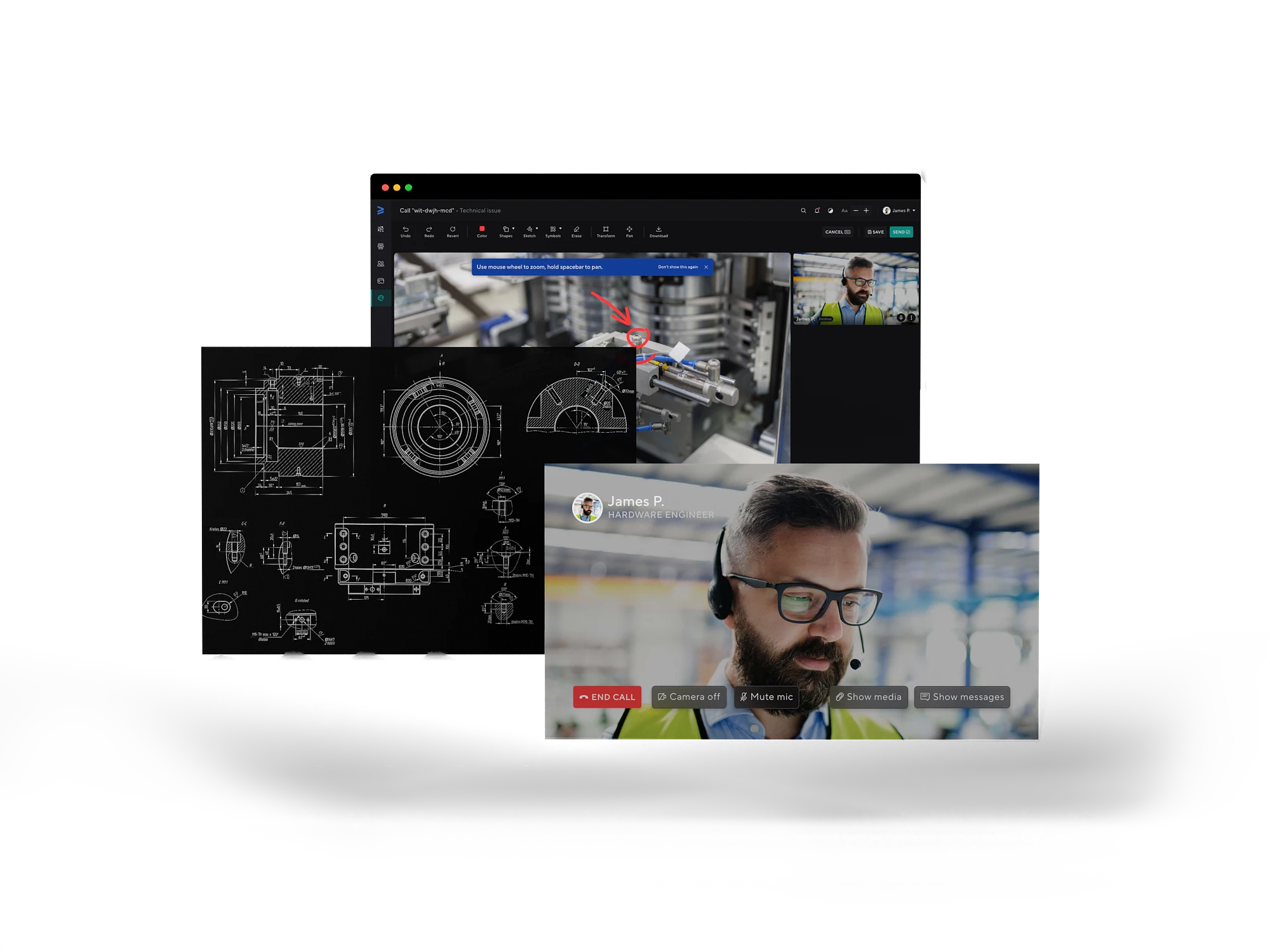

Two main modules of the platform answer directly the needs of mining enterprises, harnessing the potential of AR

The Nsflow platform is a scalable, AR-powered training tool for factory workers and engineers, combining useful features

Workflow creator

A no-code way to create step-by-step instructions to guide employees. Easy in use and not requiring specialized devices, the tool reminds of building blocks to create the desired tutorial.

Customized checklists

With Nsflow, no detail is missed. The checklists can be generated automatically and aggregate data for analysis and reporting, omitting paperwork and improving performance.

Machinery maintenance

Using AR, on-site staff can perform maintenance procedures with guidance from remote experts and benefit from high-resolution digital twins, 3D models, and holograms.

Voice and gesture operation

Voice and gesture command is crucial while working in potentially dangerous environments. Wearable AR devices recognize users’ movements and speech, leaving their hands free to perform work.

Nsflow - Benefits of augmented reality in mining

Enhanced safety

AR eliminates the need to carry and flip through excessive manuals. Expert knowledge is at arms’ length in real-time. The platform frees the hands of employees working with demanding equipment in a dangerous environment.

Reduced downtimes

Digital twins, workflows, 3D models, and holograms help in efficient predictive maintenance. AR helps to prevent malfunctions without halting mining machinery, saving precious operating time.

Cost-efficiency

Using AR allows for cutting spending on instructor costs, expert travels, machinery overhauls, eliminating results of human errors, and downtimes. Once created, digital content is ready to use and re-use as needed.

Knowledge retention

The mining industry doesn’t record an overabundance of candidates. Preparing new candidates to start safe and efficient work as soon as possible requires adjusting the training to their needs and avoiding mundane classroom training.

Learn more about our solution

Get a 14-day

FREE TRIAL

AR devices included, no risk and no cost involved.

See more use Cases

Nsflow supports industrial processes in various fields. See how AR changes the modern industry

Digital workflows

Retain and standardize knowledge in your company with interactive training, instructions, and service procedures.

Remote FAT

Check equipment and machinery functionality and quality before they leave the production line – remotely.

Nsflow Box

On-premise AR solution allowing employee training and support, protecting confidential industrial data