Augmented Reality in the Oil and Gas Industry

AR digitalizes processes in the oil & gas industry, one of the major powers of the energy sector

The oil&gas industry

The oil & gas industry, exceeding $2.1 trillion worth as of 2021 and 1.7 million employees globally, includes exploration, refining, transporting petroleum, and its derivatives.

Challenges

Occupational hazards

The industry related to highly flammable and explosive materials and complex processes is inextricably associated with constant threats to the company’s properties, human life, and health.

Business continuity

Companies operating in the ever-changing industry need to respond to its dynamics and demands in order to maintain business advantages, profitability, and increased equity position.

Operational downtimes

The industry suffers heavily each time an interruption occurs. Technical failures, lack of maintenance, and human errors halt mining and processing machinery affecting productivity.

Information flow disruptions

Lack of standardization in data gathered and shared across the industry, no tools aimed at retaining knowledge from more retiring employees result in uneven staff expertise.

Get to know more

Augmented Reality oil and gas industry solution

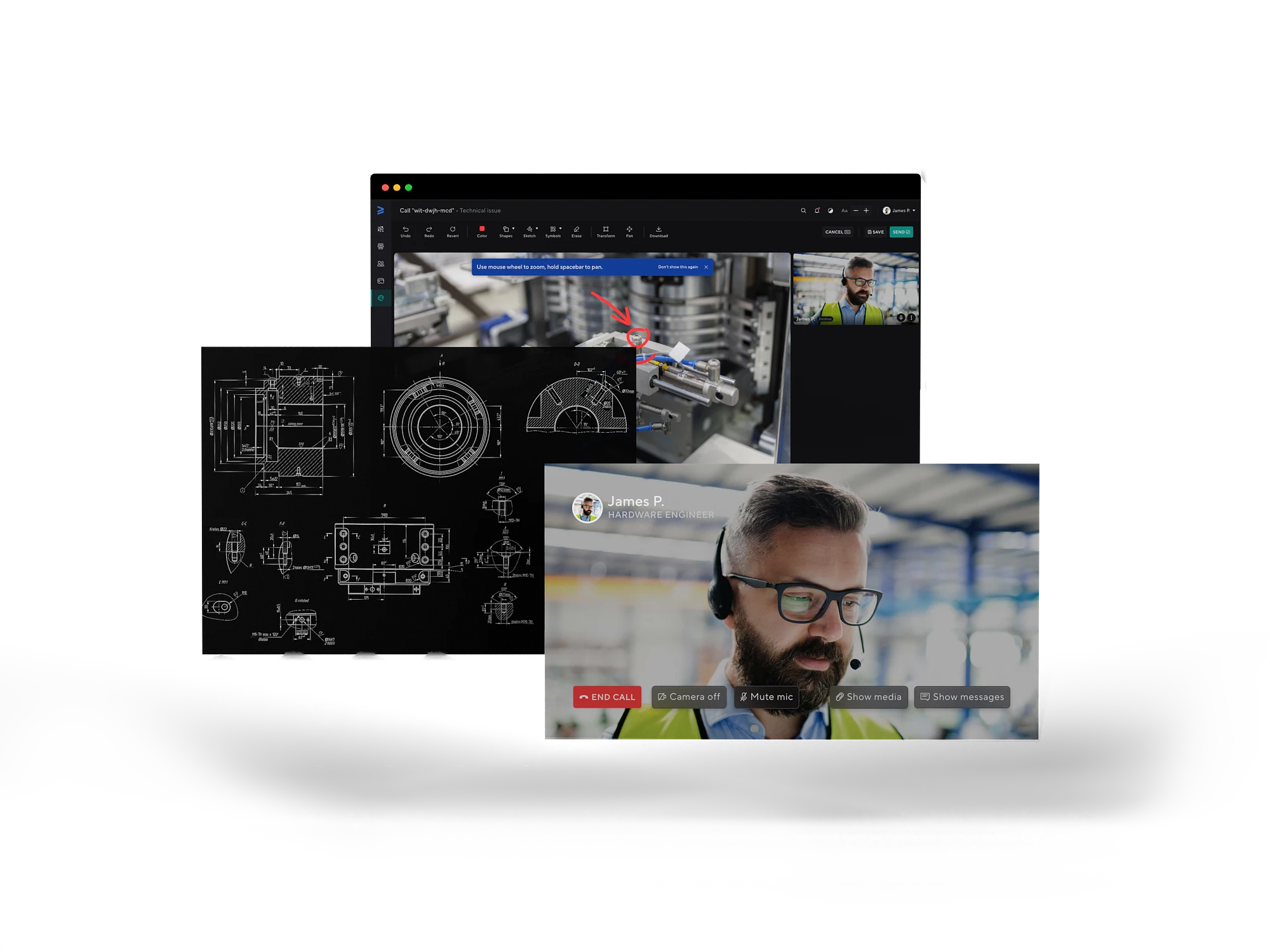

The AR platform carries two main modules, aimed at solving industrial challenges in the oil & gas field

The following features are at hand to support the execution of processes in the oil & gas industry using AR

Real-time access

AR grants users direct, immediate access to gathered resources, as the platform stores procedures, documentation, checklists, and can gather data from internal systems like SCADA, MES, ERP.

Workflow creator

No coding skills are needed to create step-by-step instructions for employees. The set-up reminds of building blocks and requires no specialized devices.

Digital twins

Virtual clones of machinery and other physical objects support predictive maintenance, helping employees glance inside the mechanisms without disassembling them and stopping operations.

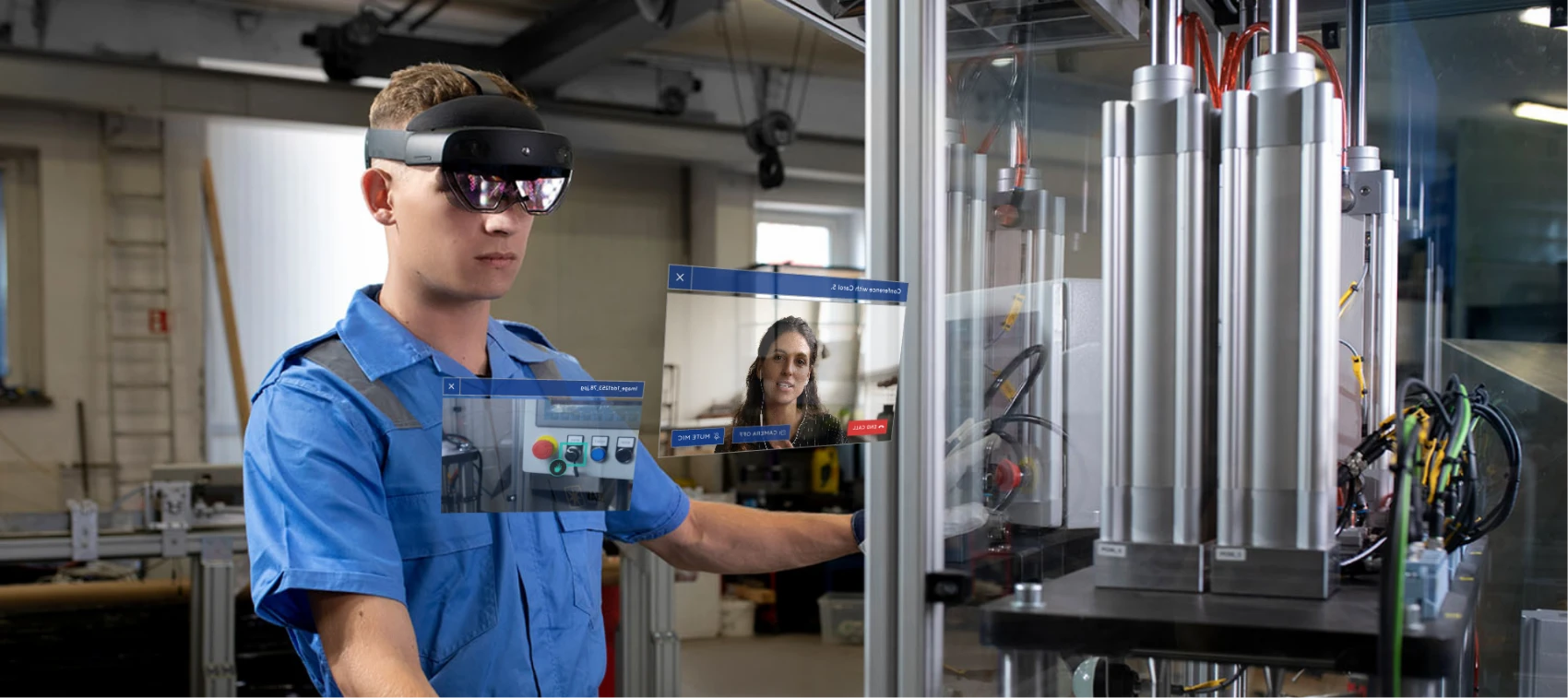

Heavy-duty potential

The platform is compatible with the most advanced devices used with protective gear, allowing freedom of movement. Convenience is crucial for staff working in demanding environments.

Nsflow - Benefits of Augmented Reality in Oil and Gas Industry

Risk mitigation

Real-time expert support helps guide on-site employees through potentially dangerous situations, allowing them to overcome machine failures without compromising safety.

Improved cost-efficiency

The AR platform facilitates savings by reducing the need for employee travel and accommodation, as well as by minimizing human errors and expenditures on traditional training.

Reduced downtimes

Supporting industrial processes with AR allows a significant reduction of interruptions, due to predictive maintenance and faster recognition of errors in the production environment.

Retained knowledge

Digital assets contain standardized training resources and instructions, available to workers also after previous generations of experts retire, eliminating issues with the so-called tribal knowledge.

Learn more about our solution

Get a 14-day

FREE TRIAL

AR devices included, no risk and no cost involved.

See more use cases

AR helps to solve various industry-specific problems. Find out more about the potential of augmented reality:

Industrial onboarding

Get your employees ready to work with step-by-step AR training, with minimal instructor engagement.

Remote FAT

Check equipment and machinery functionality and quality before they leave the production line – remotely.

Remote Support

Eliminate the distance barrier between your technicians working in the field and experts.