Empowering industrial integrators with AR

Augmented reality brings a new quality to services offered by integrators to deliver future-proof systems to industrial companies

The industrial integrators field

Industrial integrators combine various hardware and software systems to create comprehensive IT solutions to support companies in achieving their goals.

Challenges

Factory acceptance tests (FAT)

Acceptance by the client is the crowning of the machinery production process. Even in conditions precluding in-person presence, the FAT are necessary to assure the new system meets requirements and specifications.

Data storage and security

Operating state-of-the-art systems is associated with extensive datasets processing. It requires the highest security standards to protect data confidentiality and to comply with internal policies.

Integration matters

Industrial integrators work with different hardware and software systems, fitting them into factory layouts. Integration professionals need tools for streamlining operations in production conditions, bridging various technologies.

Knowledge management

Acquiring and retaining expert knowledge in the fast-paced industrial environment calls for tools tailored to meet the needs of integrators. Technology is constantly evolving and experts in the field seek solutions allowing rapid response to incoming changes.

Get to know more

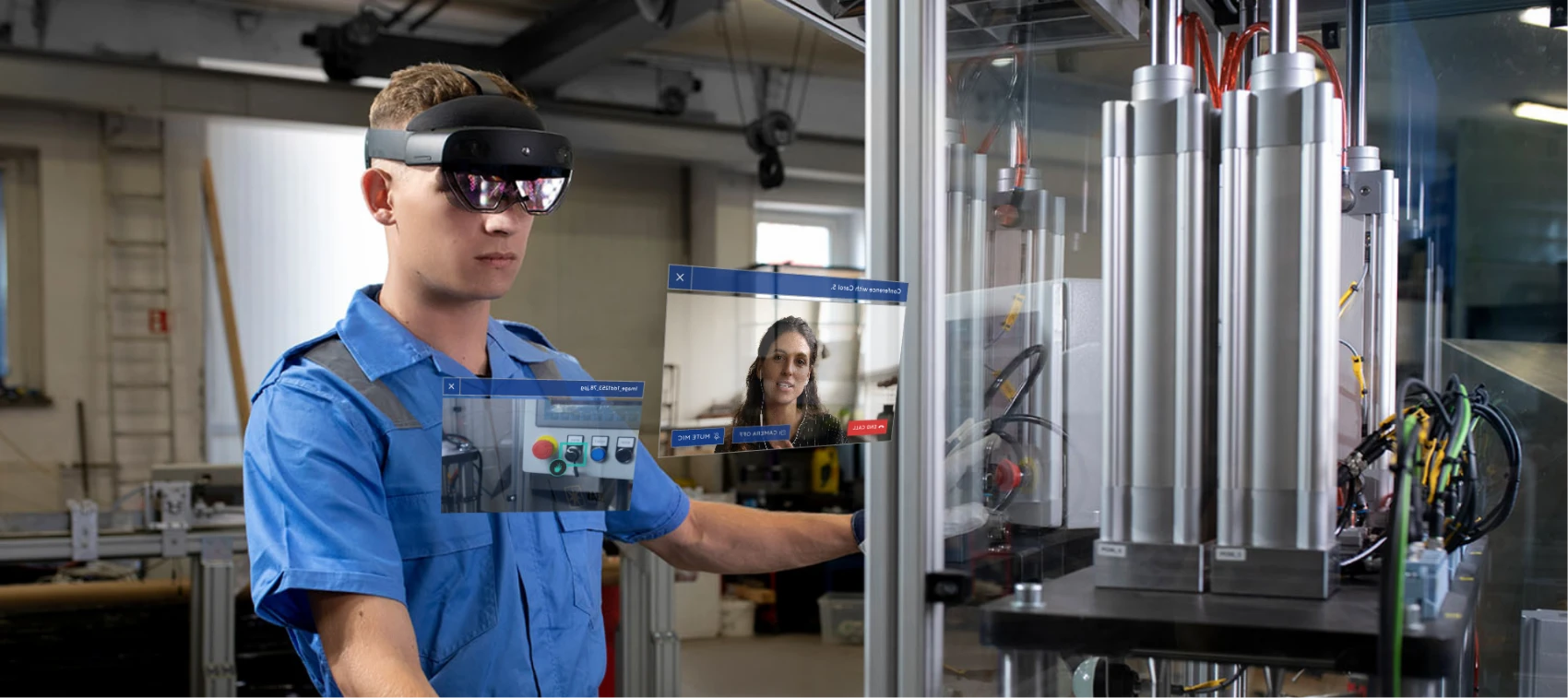

The solution

Including AR in industrial system integration processes ensures efficiency and security

The Nsflow platform offers a variety of features to streamline industrial integration operations

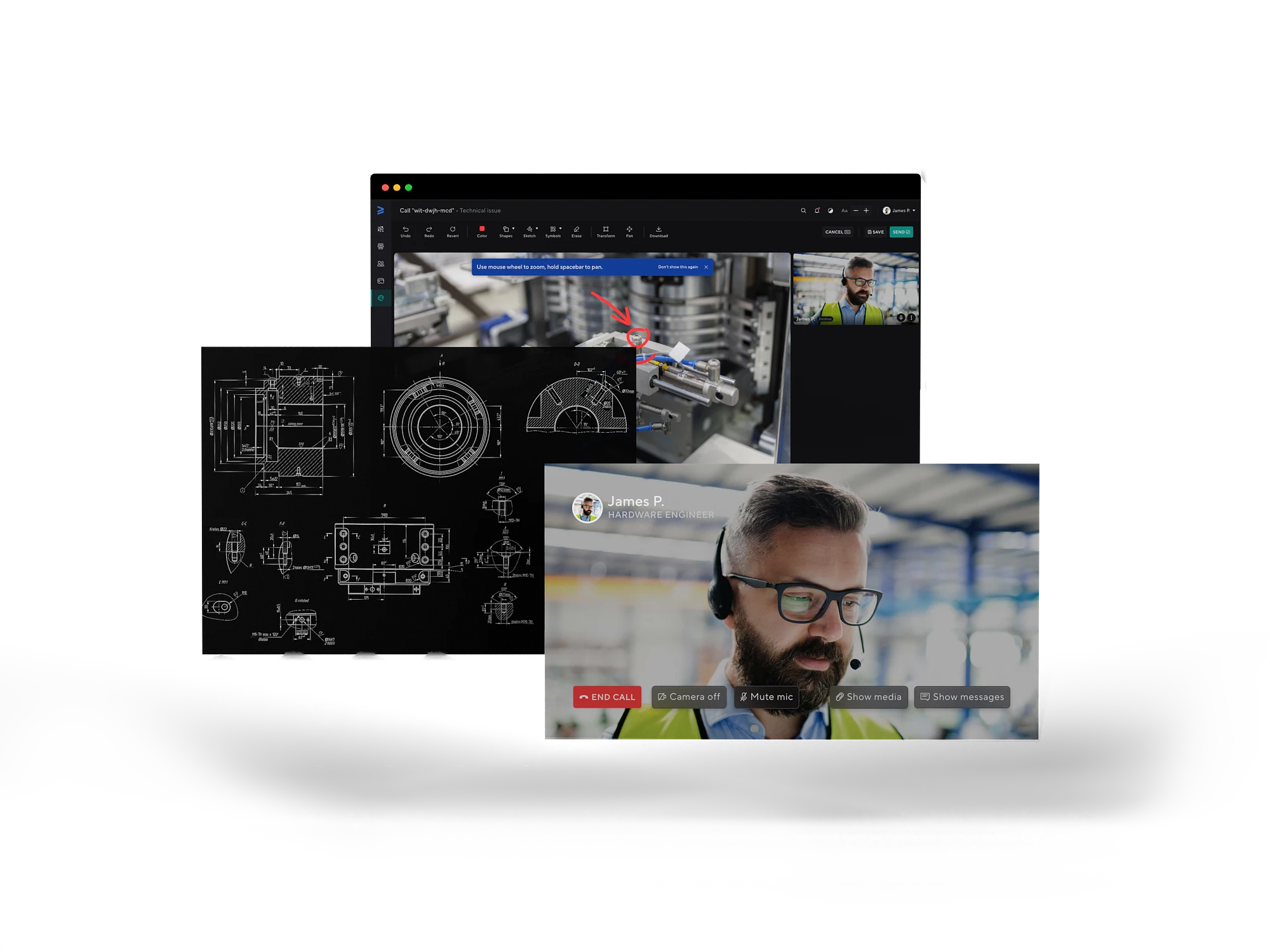

Remote FAT

Executing remote factory acceptance tests with AR allows for meeting project deadlines and protecting machinery suppliers from adverse conditions preventing on-site conduct.

Data management

Details regarding operated hardware and gathered data can be conveniently stored in the platform. Easy creation of reports, protocols, and checklists streamlines integration processes.

Digital twins

Integration experts can use digital representations of assembled machinery to present and assess its operations. Digital twins aid various processes, such as maintenance and training.

Training management

Augmented reality supports efficient learning and provides 24/7 access to standardized digital content. The platform aggregates necessary resources facilitating transfer to paperless factory.

Benefits of Nsflow

Highest security standards

The Nsflow platform comes in various forms, and the Nsflow Box allows for on-site deployment without the need for external connectivity. It is a plug&play solution that brings together the benefits of AR with internal security policies.

24/7 access

The AR platform works round-the-clock, offering assistance to on-site and remote professionals working on system integration. Operations can be executed anywhere and anytime.

System management

Augmented reality allows viewing machinery on the factory floor using digital models, prior to physical installation. Digital layouts help dispel doubts about whether the setup will match the environment or whether operator space will be sufficiently ergonomic.

Knowledge retention

Once created, tutorials are available to users and can be used anytime. With easier access to expertise, the risk of errors and downtimes is minimized and doesn’t endanger operational continuity.

Learn more about our solution

Get a 14-day

FREE TRIAL

AR devices included, no risk and no cost involved.

See more use cases

AR changes the way industrial processes are carried out, improving capabilities and competencies

Industrial onboarding

Reduction of instructor involvement shifting the training process from the traditional classroom model to a hands-on approach.

Remote support

Establishing real-time, functional communication between experts and on-site workers.

Remote FAT

Assessment of equipment and machinery regardless of external conditions to assure the highest quality.