Digitalizing the industrial machinery & equipment sector

Augmented reality transforms operations carried out by companies providing machinery and equipment in the industrial sector

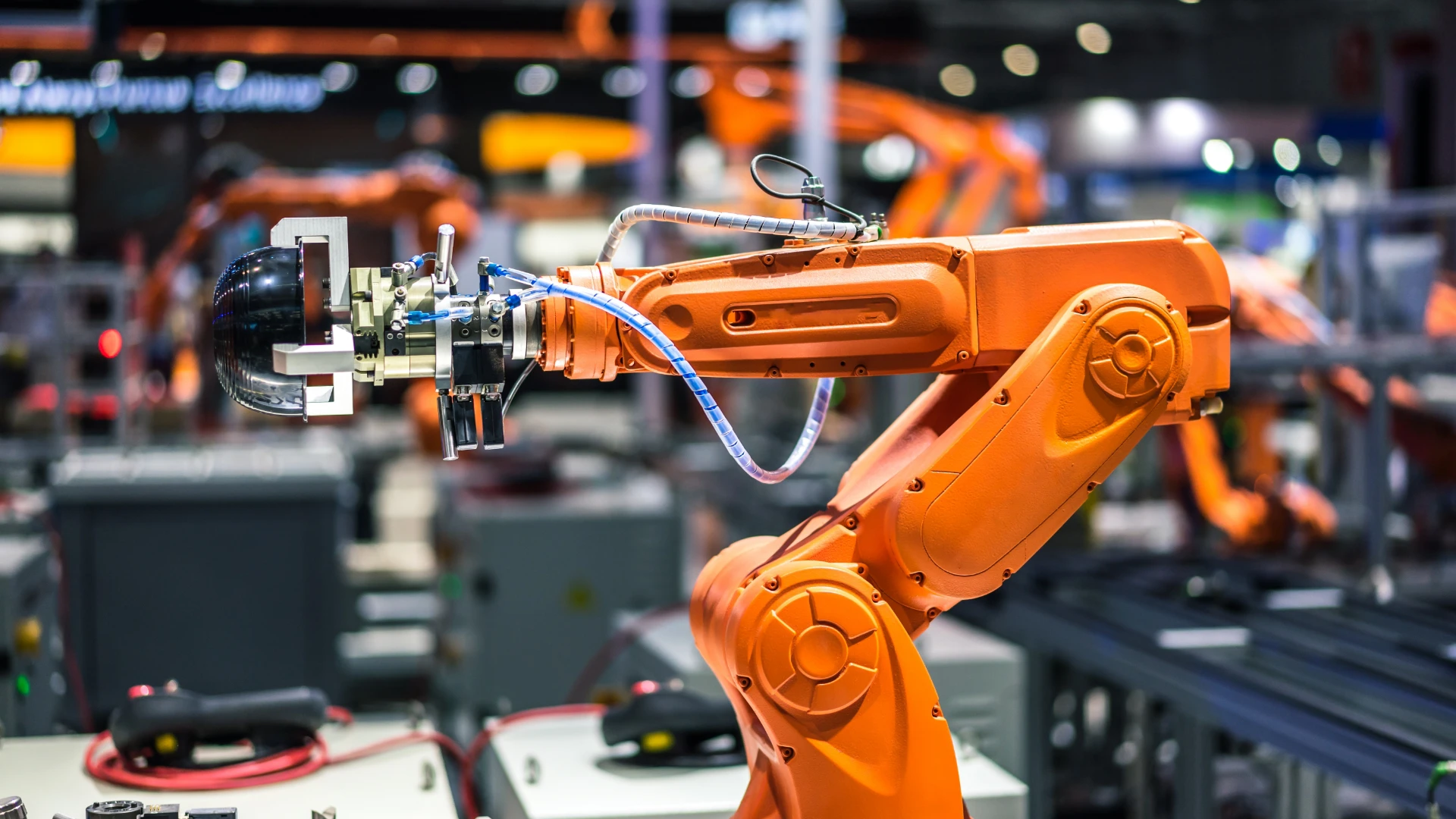

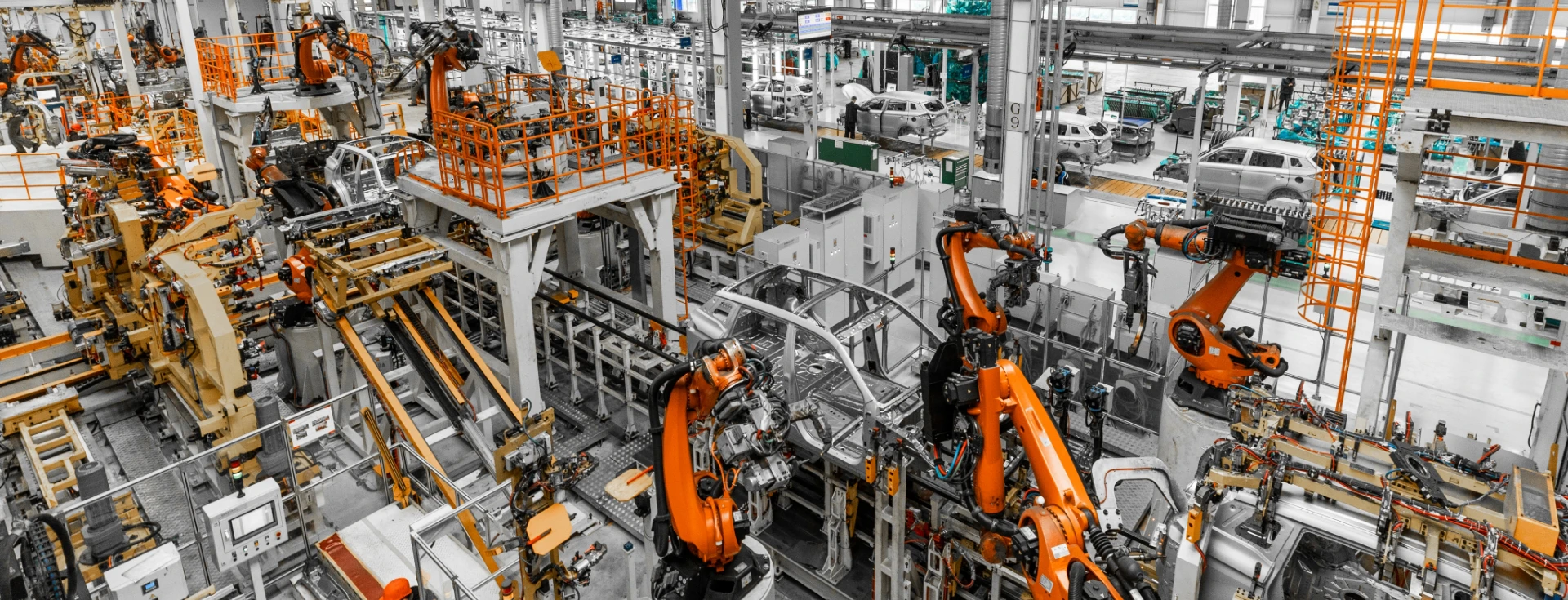

The industrial machinery sector

Heavy equipment and machinery suppliers respond to emerging needs in various industries, delivering relevant devices to sustain manufacturing continuity.

Challenges

Cost management

Remaining competitive is no small feat in the industry depending on many variables. Rising raw material costs, staff deficit, and production downtimes add up to significant expenses.

Service flow challenges

The industry operates in adverse conditions. Machinery suppliers aim to employ tools streamlining the acceptance, service, maintenance, and overhaul processes to preserve operational continuity.

Staff security

Operating heavy machinery is always burdened with risk. Companies need to focus on occupational safety processes to ensure an accident-free environment, which can be achieved by in-depth employee training.

Competencies management

The industry faces an ongoing generational change and employee churn. Retaining expert knowledge and passing it on to new hires calls for decisive, efficient measures and adequate tools.

Get to know more

The solution

Adopting AR into daily operations answers challenges faced by industrial machinery & equipment suppliers

A wide selection of dedicated features that simplify processes of industrial companies and improve efficiency

Service checklists

Digitized instructions are available for staff 24/7, instructing employees on every step of a procedure. Standardized files simplify the execution and improve accuracy.

3D models and holograms

Life-like models of machinery facilitate the execution of maintenance and service processes, giving better insight into equipment functioning without disassembly.

Easy access to data

Data obtained from executed processes can be used to automatically generate protocols and reports. Improved data management allows efficient progress tracking and optimizing results.

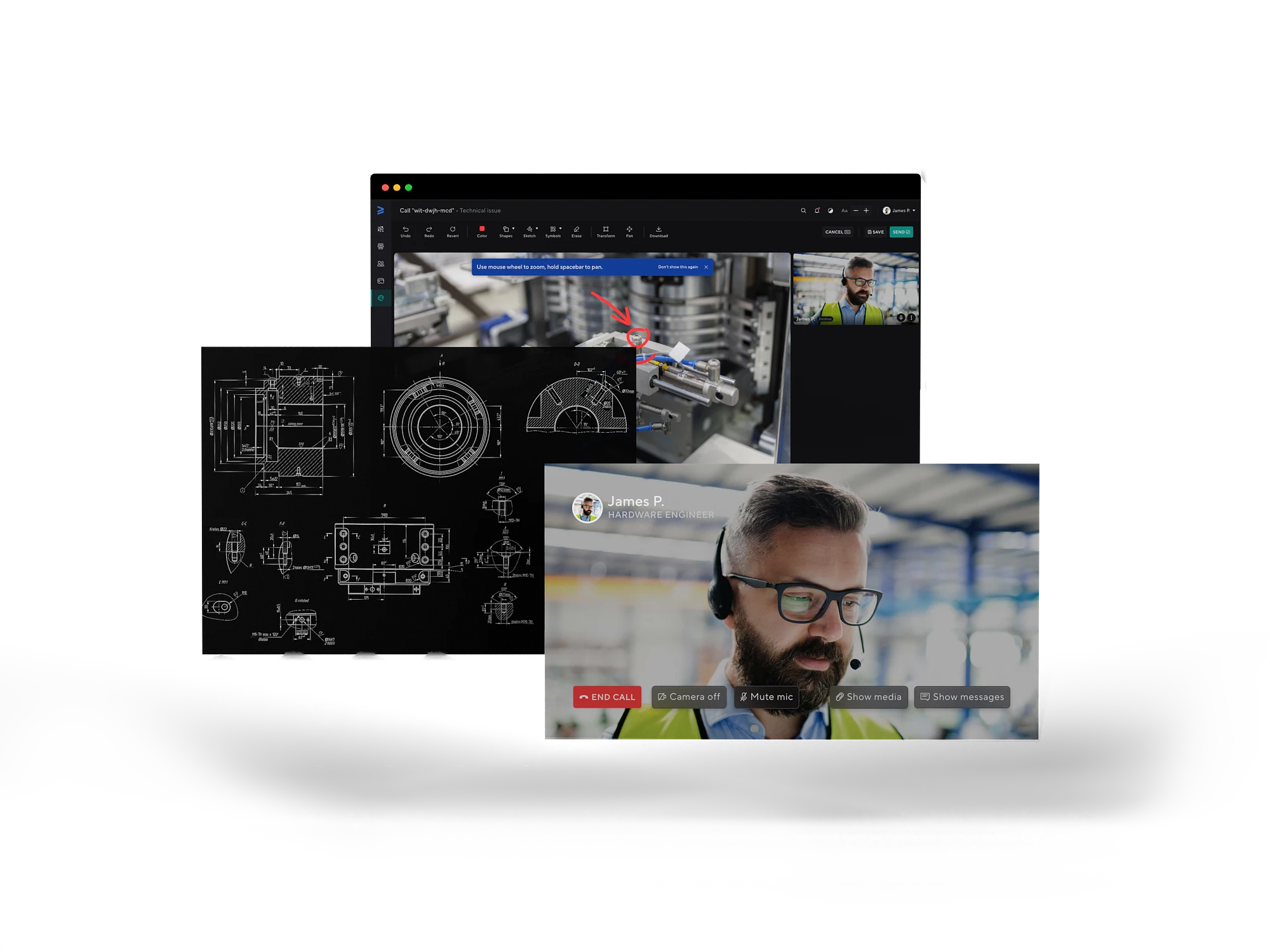

Remote FAT

Acceptance procedures are an inherent part of the industry. Performing FAT remotely immunizes suppliers from external adverse conditions, securing timely delivery.

Benefits of Nsflow

Improved safety

With the ongoing access to instructions and guidelines staff can reassure on performed actions anytime it’s necessary, reducing the risk of accidents and human errors.

Cost reduction

Shortening classroom learning in favor of hands-on training saves costs of instructors, training materials, and improves progress assessment.

Easy 24/7 access

Whether it’s drawing conclusions from data on previous process iterations or launching another service manual, the platform is available to staff on every shift.

Knowledge management

Chasing away the tribal knowledge issues, the platform allows to aggregate all internal expertise to be used by staff. Less paperwork, more insights on progress.

Learn more about our solution

Get a 14-day

FREE TRIAL

AR devices included, no risk and no cost involved.

See more use cases

See how the potential of AR serves various industries. Nsflow proves to transform demanding processes:

Industrial onboarding

Reduction of instructor involvement shifting the training process from the traditional classroom model to a hands-on approach

Remote FAT

Assessment of equipment and machinery regardless of external conditions to assure the highest quality

Remote support

Establishing real-time, functional communication between experts and on-site workers