Digitalize production processes in the machinery industry

Take advantage of augmented reality in daily operations to respond to the most significant challenges of the machine industry

The manufacturing industry

The multi-billion worth market comprises roughly 15% of the global GDP. Benefitting from the latest technology, delivers the highest quality products made in a safe, modern environment.

Challenges

Skilled labor gap

Due to the outflow of experienced workers, companies need modern, efficient training. The standardized, accessible process helps to preserve production flow, equipping new hires with necessary skills.

Improving efficiency

Manufacturing companies require the involvement of technology improving production, assembly, enhancing performance to remain competitive in the competitive market, delivering products answering customer needs.

Maintenance

Conservation calls for real-time access to data and monitoring, allowing technicians to forecast possible disruptions. Continuity of production is secured by service carried out in the least intrusive way.

Get to know more

Augmented Reality Solutions for Manufacturing

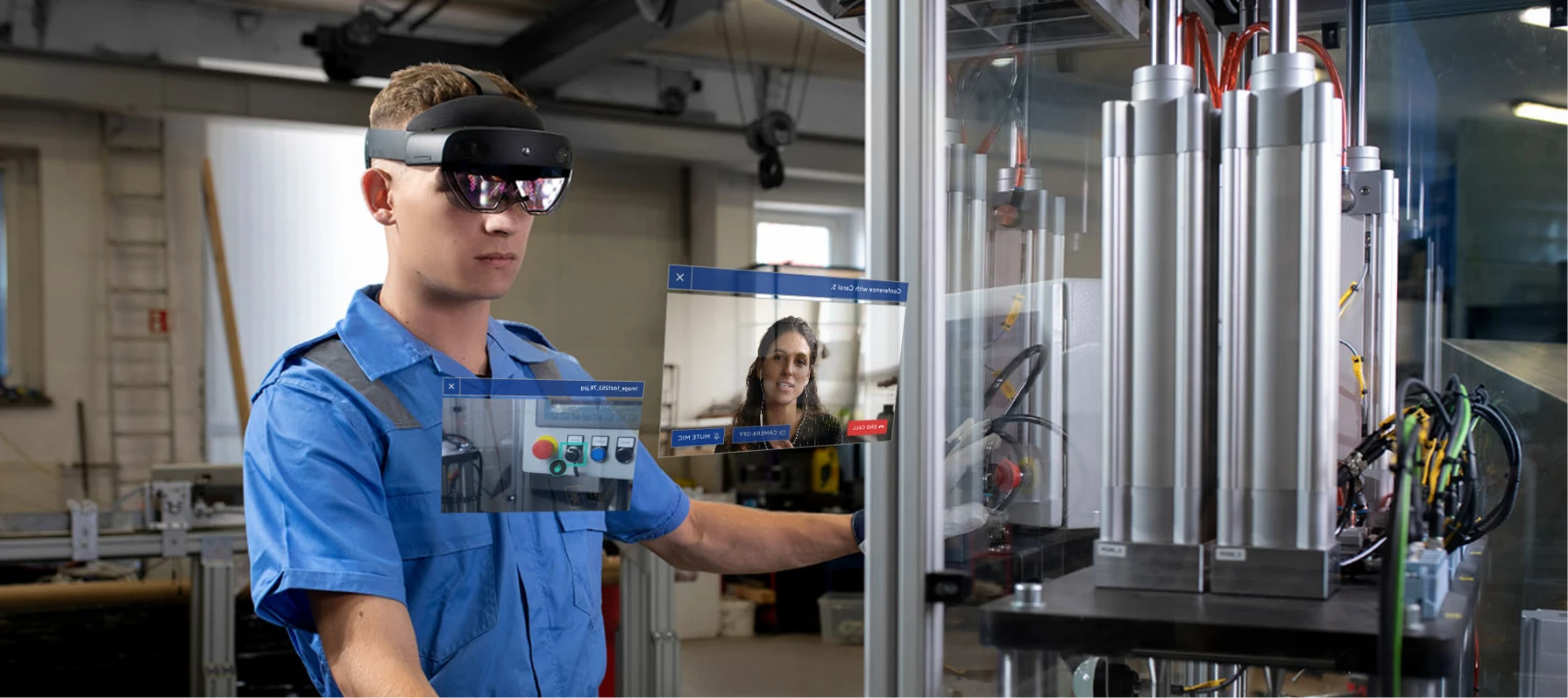

AR reshapes manufacturing as we know it, as new technologies are widely adopted by enterprises

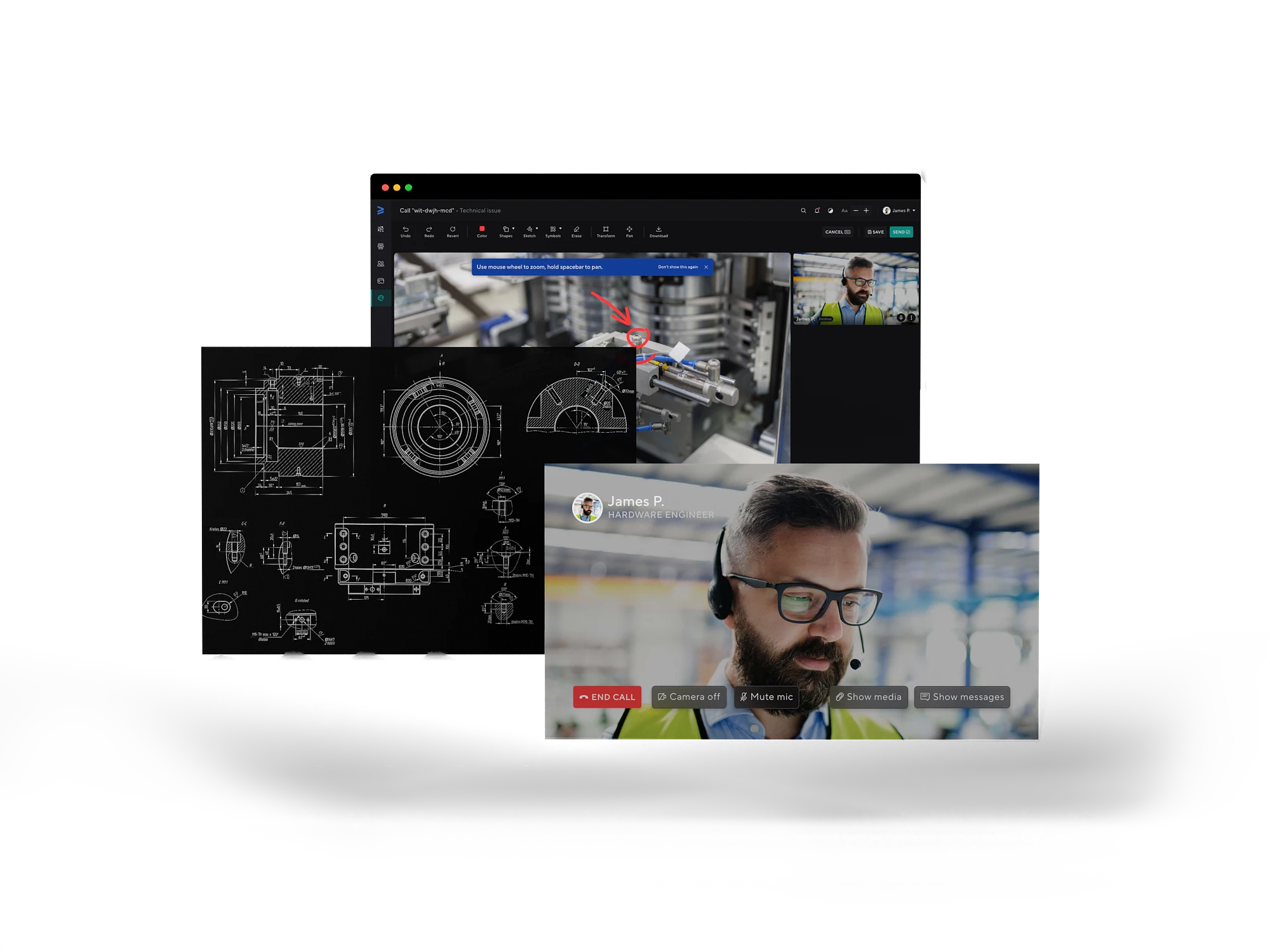

The Nsflow platform is a scalable, AR-powered training tool for factory workers and engineers, combining useful features

Digital twins

With Nsflow, users can create a realistic digital representation of objects. Simulating operations on real-life machinery results in insights on equipment performance and maintenance needs.

Contribution to safety

Nsflow supports technicians working in heavy industries. The platform cooperates smoothly with various wearable devices, enabling unimpeded usage of safety goggles and hard hats.

Streamlined employee training

The platform liberates employees from classroom learning, enabling hands-on experience during on-the-job training, improving onboarding and learning management, reducing trainers workload.

Easy access to data

The platform aggregates documentation, interactive checklists, service procedures, and displays data from systems including SCADA, MES, ERP, providing online, 24/7 access to resources.

Nsflow - Benefits of Augmented Reality in Manufacturing Industry

Cost efficiency

Augmented reality in manufacturing allows reducing costs of human errors, time-consuming classroom training, malfunctions causing downtimes, and business travels.

Standardized knowledge transfer

Once created, tutorials are widely available, eliminating challenges related to generational change and tribal knowledge, and ensuring consistent skills levels.

Improved on-site safety

AR supports frontline workers, serving as an additional measure of safety, detecting potential threats, preventing on-site accidents, enabling hands-free, unrestricted operations.

Reduced downtimes

Nsflow supports service and maintenance procedures, bringing staff focus to problematic areas, eliminating errors, and resulting in improved business continuity.

Learn more about our solution

Get a 14-day

FREE TRIAL

AR devices included, no risk and no cost involved.

See more use Cases

Nsflow supports industrial processes in various fields. See how AR changes the modern industry

Industrial onboarding

Get your employees ready to work with step-by-step AR training, with minimal instructor engagement.

Remote FAT

Check equipment and machinery functionality and quality before they leave the production line – remotely.

Remote Support

Eliminate the distance barrier between your technicians working in the field and experts.