Digitalize production processes in the food industry

Take advantage of artificial intelligence and augmented reality to respond to the most significant challenges of the food industry

The food industry

The food industry is a diversified network of companies that are involved in farming, food production, packaging, transportation, and distribution. It involves not only global corporations but also family-run firms.

Challenges

Staff shortages

Even though a lot of processes have become highly mechanized, the initial stages of the production process are particularly labor-intensive, facing staff shortages in peak season.

Product quality

From fresh produce, through uncontaminated processed food, to the right storage and transport conditions – each stage of the process has to be strictly controlled. Any aberrations can put consumers’ health at risk.

Production efficiency

The FMCG market is particularly price-sensitive. Thus, companies strive to improve the process efficiency to produce food at the lowest possible cost, maintaining its quality and health safety.

Time is money

Since the industry often deals with fresh produce, machinery downtimes or disruptions in the supply chain can cost a small fortune. Every minute matters when it comes to fruit, meat, dairy, etc. freshness.

Get to know more

The solution

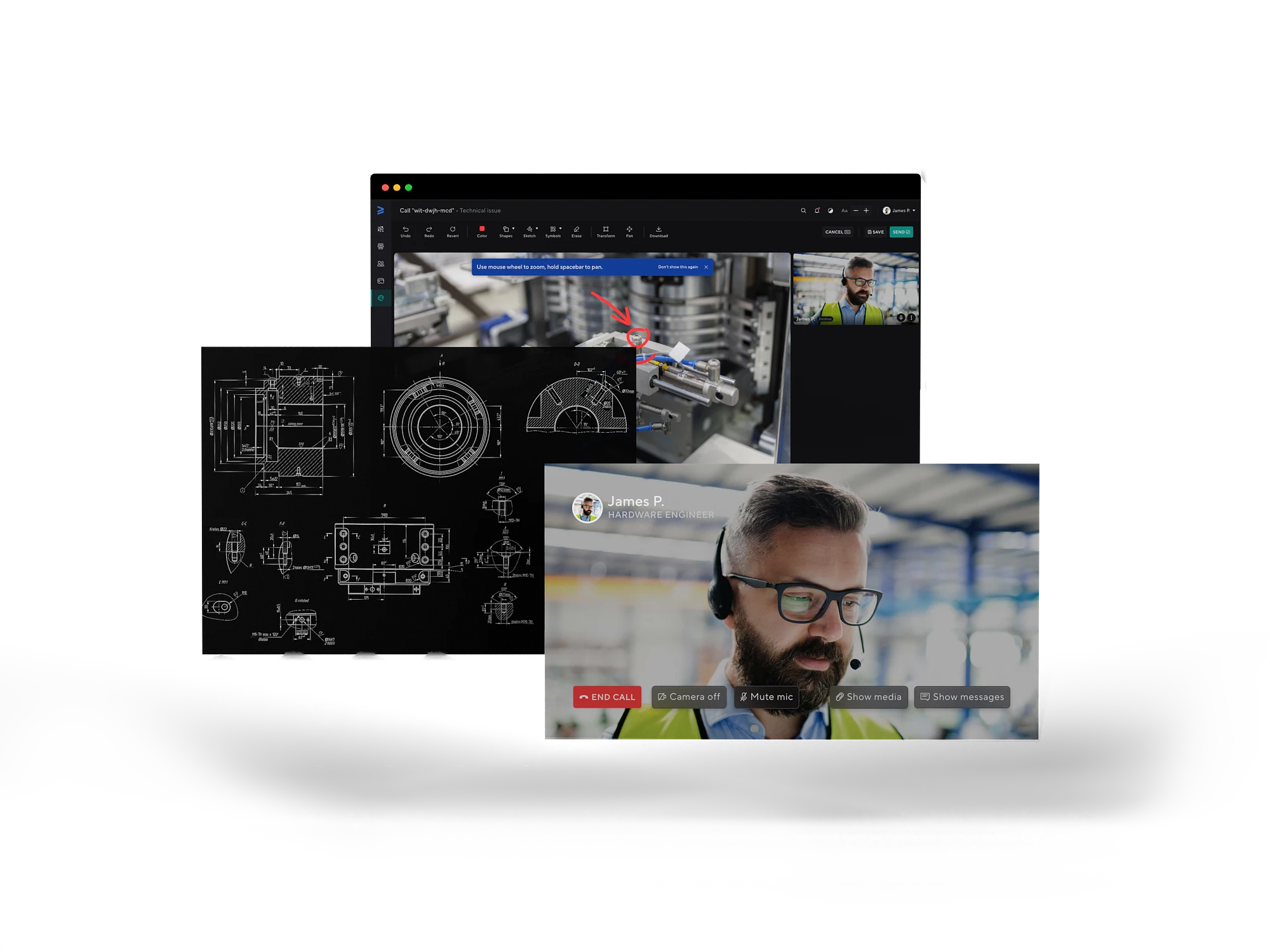

The answer to the food industry challenges is a digital platform powered by AR, with two ready-to-use modules

The key features that will boost your production processes and product quality

Training automation

Address the problem of staff shortages with augmented reality training. Learning by doing takes less time than classroom activities and involves minimal trainer involvement.

Procedure checklists

Prepare checklists of tasks to perform or product attributes to verify by your employees. This way, you can be sure of the constant high product quality across all your factories.

Machinery maintenance

Carry out production machinery maintenance and service procedures remotely to minimize downtimes. No more waiting for technicians to get to the production plant.

Detailed reporting

With the admin panel, you can quickly identify areas causing bottlenecks, such as machinery that has to be serviced more often or employees that are less attentive to product quality.

Benefits of Nsflow

Cost effectiveness

Nsflow allows you to cut costs of staff onboarding, training, machinery service, and reduce human errors and downtimes. Integrate it with your systems for predictive maintenance.

Improved quality

Company know-how stored in digital form, standardized training, assessment checklists, and remote assistance help you to improve the quality of food products you manufacture or distribute.

Process optimization

Use Nsflow to measure your process efficiency. Identify problematic areas to improve production time, produce less wastage, and automate a variety of tasks.

Business continuity

Secure your business going paperless, automating training, digitizing production processes, and company know-how. Introduce AR procedures for unexpected events.

Learn more about our solution

Get a 14-day

FREE TRIAL

AR devices included, no risk and no cost involved.

See more use cases

Nsflow solutions can be adopted in a variety of industrial scenarios to optimize your business processes.

Industrial onboarding

Reduction of instructor engagement with step-by-step digital training to speed up integration of new hires

Remote FAT

Convenient verification of machinery performance and operations executed remotely

Nsflow Box

An industrial-grade solution for on-premise AR deployment, improving data security