Factory Acceptance Testing

Perform factory acceptance tests remotely, thanks to augmented reality.

What is FAT?

Check equipment and machinery functionality and quality before they leave the production line.

Get to know more

Verify machinery quality

Factory acceptance testing verifies that newly manufactured machinery and components meet all requirements. The process takes place before delivery, still at the production plant.

An essential step

Being cost-effective, FAT pertains to every manufacturer. Clients verify machinery beforehand, which minimizes the problems that might take place during the installation.

Operational continuity

The inability to perform FAT might seriously affect your business continuity. Successful acceptance test means the whole project can be finished as planned.

FAT Challenges

Completing scheduled FAT is a crucial step in the project execution, but it also faces some serious problems.

Sanitary restrictions

As the Covid pandemic has shown us, some challenges might be hard to foresee. They include travel bans, sanitary restrictions, and quarantine imposed.

Human error

FAT is performed by humans which involves the risk of human error. They may forget to test some crucial features and accept incomplete or even defective equipment.

Insufficient resources

Performing FAT in person requires expert participation and taking into account health issues, their availability, and time spent on traveling.

Unforeseen delays

Travel bans, traffic accidents, employee indisposition, etc. can greatly affect the time FAT will take place and as a consequence the whole project timeline.

What troubles your company?

We will be happy to discuss your needs and possible solutions.

The solution

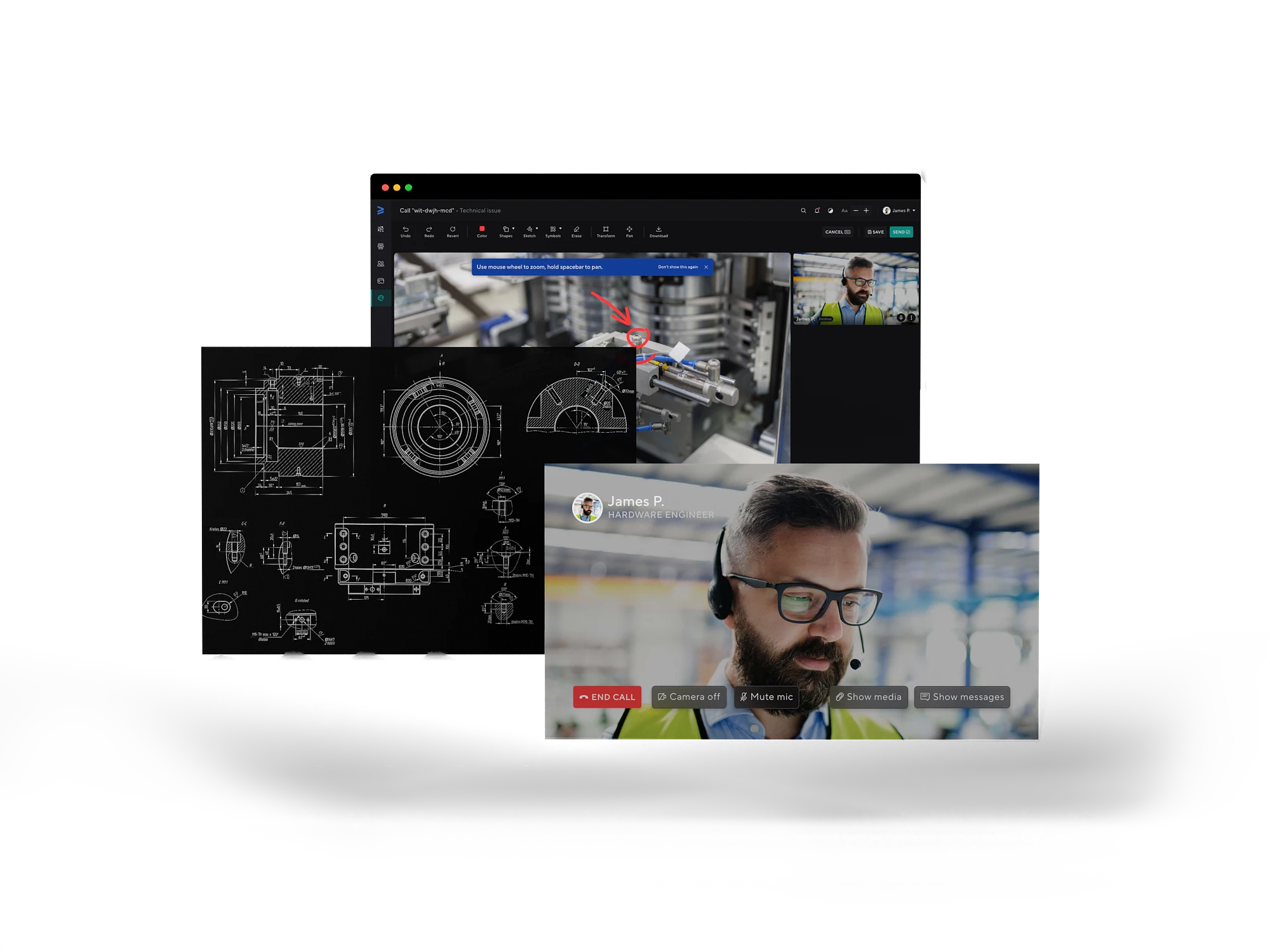

The answer to the FAT challenges is a platform supported by AR with its two main modules:

Factory acceptance testing made easy

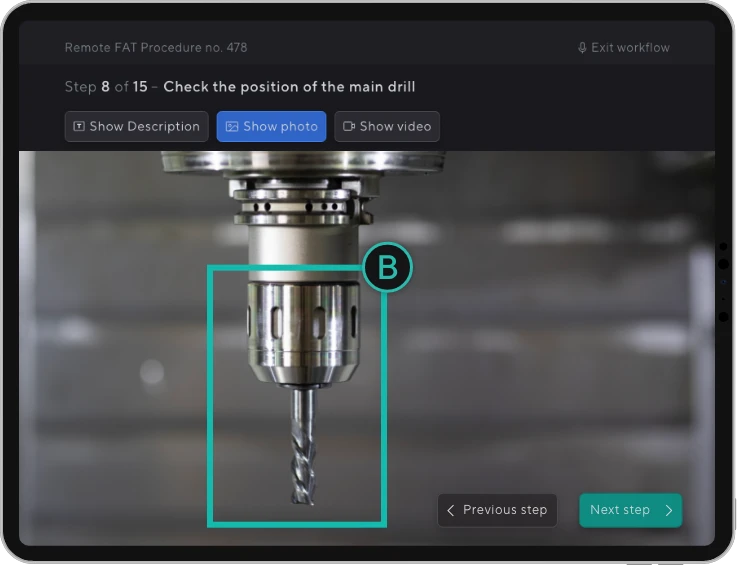

Remote FAT

The tests take place online in real-time and the physical presence of a client’s representative is replaced by augmented reality. It is just as efficient as the traditional execution.

Safety and efficiency

We’ve made remote factory acceptance testing not only possible but also safe and efficient. There is no need for personal visits and business trips anymore.

More than calls

You can make real-time calls with the option to take pictures, add annotations to the images, send files, and share your screen. Only the person standing by the machine needs an AR device.

Augmented reality

During the real-time video call, a manufacturer’s representative is equipped with an AR device. It transfers first-person view of operations carried out on the machine.

The benefits of AR-powered FAT

Remote FAT is faster

With no traveling, it’s easier to arrange and conduct FAT. It means a quicker response to technical issues, immediate transaction closure, and earlier access to new machines.

Remote FAT is cheaper

Remote FAT reduces the need for costly business travel and accommodation. Instead of writing lengthy test documentation, it can be recorded and saved in the system.

Your business is independent

As FAT can be completed regardless of travel or sanitary restrictions, there are fewer factors threatening your daily operations and the company becomes more self-sufficient.

All processes are documented

You can record FATs to revise and share them with your employees or stakeholders. It applies also to all documents, photos, and messages sent during the session.

Learn more about our solution

Get a free 14-day trial*

*AR devices included, no risk and cost involved