Tackling challenges in the chemical industry with AR

The power of AR in daily operations responds to the most common challenges of the chemical industry

The chemical industry

Chemical companies manufacture goods crucial to the global economy. To maintain their market position and highest quality, they need to stay up-to-date with the newest technologies.

Challenges

Lack of personnel

A high turnover of staff and the time-consuming onboarding process affect manufacturing continuity. Without skilled employees, plants face disruption in production and completing orders.

Quality assurance

Chemical processing requires the highest standards of operations, as it deals with toxic substances. Failures may have dire consequences, posing threat to human life and the environment.

Manufacturing efficiency

In times of Industry 4.0, improving productivity is necessary to maintain a satisfactory market position. Digital tools can reduce errors, streamline service procedures, and gather data on performed processes.

Digitalization

The turn of the decades has shown that early adopters of digital tools gained considerable advantage. The chemical companies have a lot of digital advancements to embrace not to fall behind the competition.

Get to know more

The solution

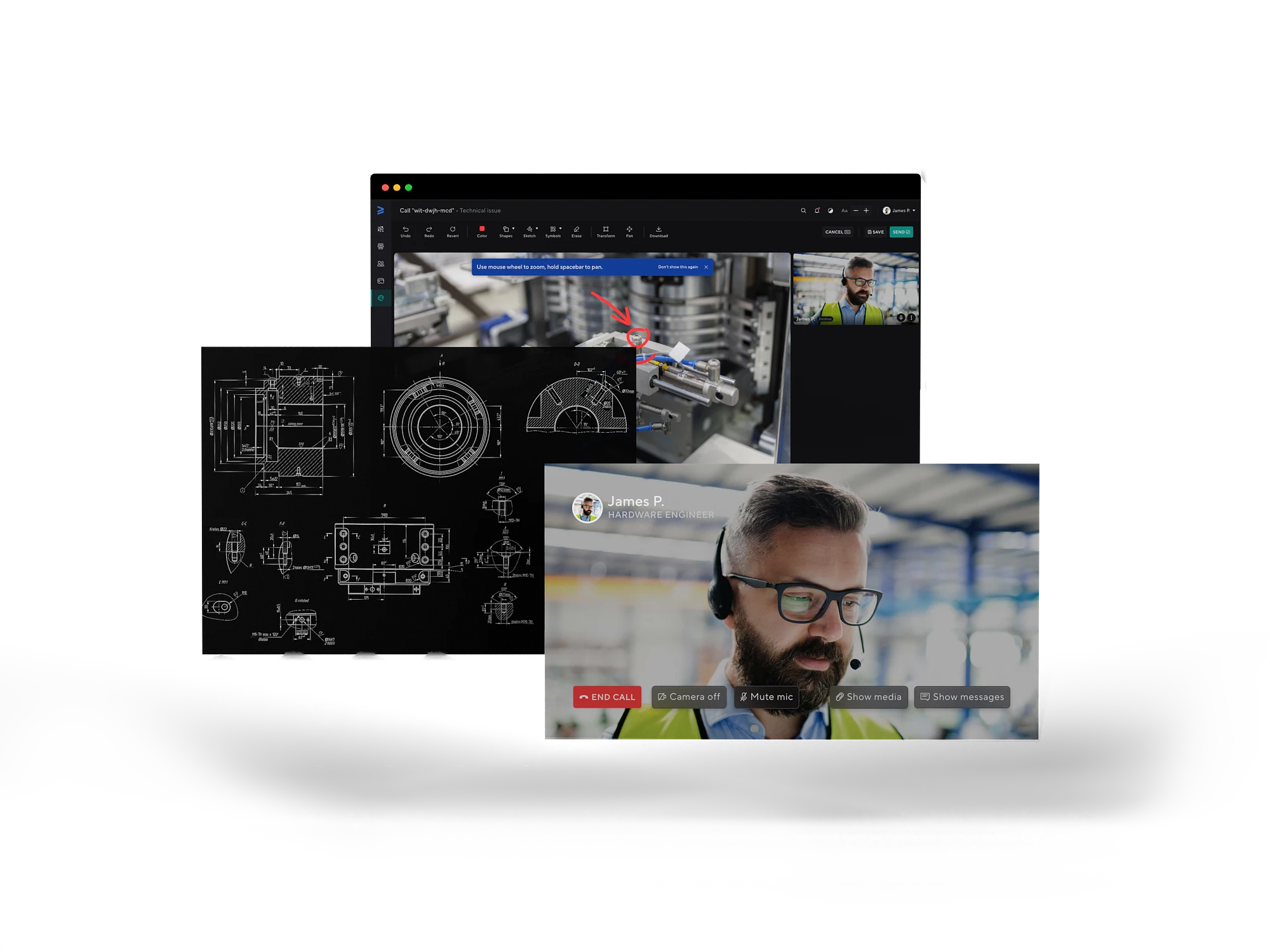

The answer to the chemical industry challenges is a platform supported by AR, with its two main modules:

Plenty of features that will boost your daily operations

Workflow creator

The platform comes with a user-friendly built-in wizard making use of a drag-and-drop tool. It enables fast and easy tutorial building. There is no need for coding skills.

3D holograms

Augmented reality enables creating life-like 3D models and holograms of machinery. Let your staff take a look at what’s under a machine’s “hood”, without disassembling it.

Service checklists

Checklists and service procedures with AR improve task performance. No more paperwork, no need to stop the procedures to make notes. Data is available for sharing, analysing, and reporting.

Quality assurance

From standardized employee training to task performance verification, Nsflow improves quality and safety of processes performed at the plant. Reduce the risk of breakdowns and human error.

Benefits of Nsflow for chemical industry

Cost reduction

Nsflow reduces high employee training costs, spent on instructors, classrooms, and travel. Once created, courses can be accessed by multiple users at the same time.

Streamlined processes

With remote access to experts you can solve problems immediately when they take place. Integration with SCADA, MES, ERP systems facilitates efficient data analysis.

Knowledge management

Nsflow enables gathering all vital information within the company, in a digital form and accessible 24/7. It applies both to paper manuals and the most experienced employees’ knowledge.

High usability

The platform can be used on various devices, including tablets and smartphones. The most advanced AR devices, though, are designed to withstand the most demanding conditions.

Learn more about our solution

Get a 14-day

FREE TRIAL

AR devices included, no risk and no cost involved.

See more use Cases

Nsflow solutions can be adopted in a variety of industrial scenarios to improve your business processes.

Industrial onboarding

Get your employees ready to work with step-by-step AR training, with minimal instructor engagement.

Remote FAT

Check equipment and machinery functionality and quality before they leave the production line – remotely.

Digital Workflows

Retain and standardize knowledge in your company with interactive training, instructions, and service procedures.