Digitalize industrial processes in the energy sector

Augmented reality and remote operations respond to the most common challenges the energy industry faces

The energy industry

From fossil fuels to nuclear power, energy companies provide for the rest of the global economy. Competitiveness and a safe working environment can be achieved with the newest technologies.

Challenges

Market transformation

Rapid system and technology transformation results in a pressing need for skilled workers that would be able to manage new processes and operate sophisticated machinery.

Lack of experienced staff

As an effect of employee rotation and aging, there is an urgent need to train new workers. However, the process in its traditional form is lengthy and demands close expert involvement.

Technical issues

Machinery breakdowns in the energy sector can be not only costly, due to overhauls and downtimes, but also life-threatening. Thus, enormous effort is put into avoiding them above all else.

Regulatory changes

The energy sector is prone to regulatory changes – on a national and international level. It is crucial that everybody in the company knows the new rules and follows them.

Get to know more

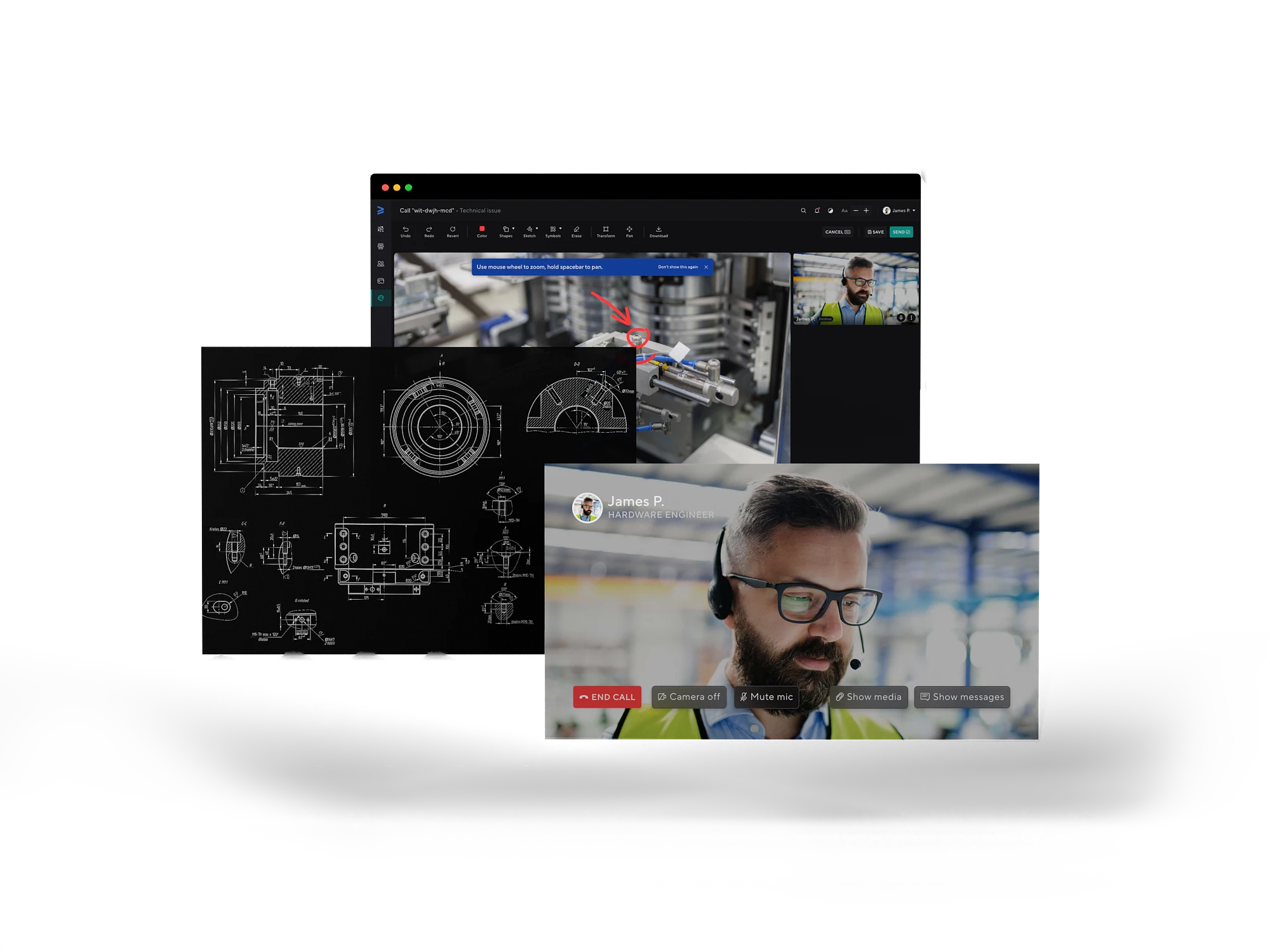

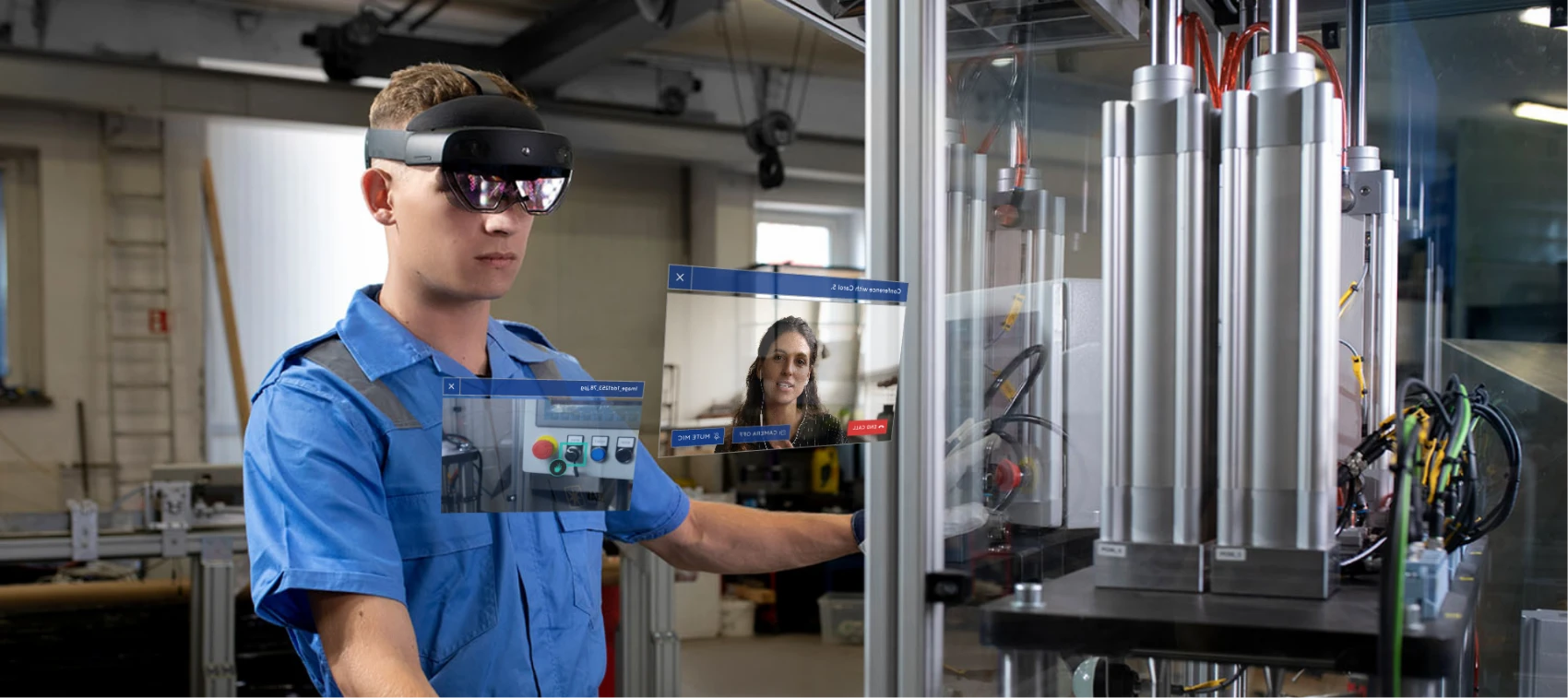

The solution - augmented reality in energy industry

Nsflow answers directly to the main challenges faced by the energy industry. The features and possibilities it offers:

Plenty of features that will boost industrial process digitalization and daily operations

Digital twins

You can use digital copies of new machinery to plan it in your energy plant, run tests on them, and train your employees before they start working with real equipment.

Automated training

With the Digital Workflows module, you can organize hands-on job training without the need for 1 to 1, trainee-expert sessions. The system is capable of verifying task correctness.

Predictive maintenance

Integrate Nsflow with internal company systems to predict and avoid machine failures. The platform will inform your employees when preventive action should be taken based on data analysis.

Hands-free operation

Working in the energy industry can be demanding in terms of conditions, such as in mines, on oil platforms. AR glasses can be operated with gestures or voice commands only.

Nsflow - Benefits of augmented reality in energy industry

Knowledge management

With Nsflow, you can keep your know-how within the company. Save maintenance and service recordings and your expert knowledge in the form of step-by-step tutorials.

Cost reduction

Nsflow reduces high onboarding and employee training costs, spent on instructors, classrooms, and travel. It also helps to avoid expensive machinery overhaul and downtimes.

Risk minimization

Checklists and instant access to knowledge minimize human error, predictive maintenance helps to avoid breakdowns, automated training assures you operate in compliance with the law.

Business continuity

Industrial process digitalization, with augmented reality and artificial intelligence, helps to secure your business against any unexpected events. Both internal and external.

Learn more about our solution

Get a 14-day

FREE TRIAL

AR devices included, no risk and no cost involved.

See more use Cases

Nsflow solutions can be adopted in a variety of industrial scenarios to improve your business processes.

Industrial onboarding

Get your employees ready to work with step-by-step AR training, with minimal instructor engagement.

Remote FAT

Check equipment and machinery functionality and quality before they leave the production line – remotely.

Remote Support

Eliminate the distance barrier between your technicians working in the field and experts.