Augmented Reality (AR) Training Platform for the Automotive Industry

Streamline your operations with an all-in-one AR platform that answers common challenges of the automotive industry

The automotive industry

As one of the main sectors, the automotive industry drives the global economy. More than 50 countries manufacture and assemble vehicles, supplying the market with millions of units yearly.

Challenges

Knowledge retention

The skills gap is a common issue affecting manufacturing industries. Experienced employees retire, and the younger generation doesn’t fill in the vacancies fast enough to keep up with the production demands.

Work safety

A safe workplace is necessary to carry out manufacturing processes. It requires a responsible approach to preventing injuries and accidents. Companies need to adjust working conditions to minimize the risk.

Process efficiency

Efficiency and profitability may be threatened due to poor data management and analysis. They are crucial to design products, answer customer needs, react to current events, and forecast demands.

New technologies

Apart from the automation of assembly lines, another new technologies play an increasingly important role in the automotive industry, such as augmented reality. Adopting them successfully can be time-consuming.

Get to know more

The solution

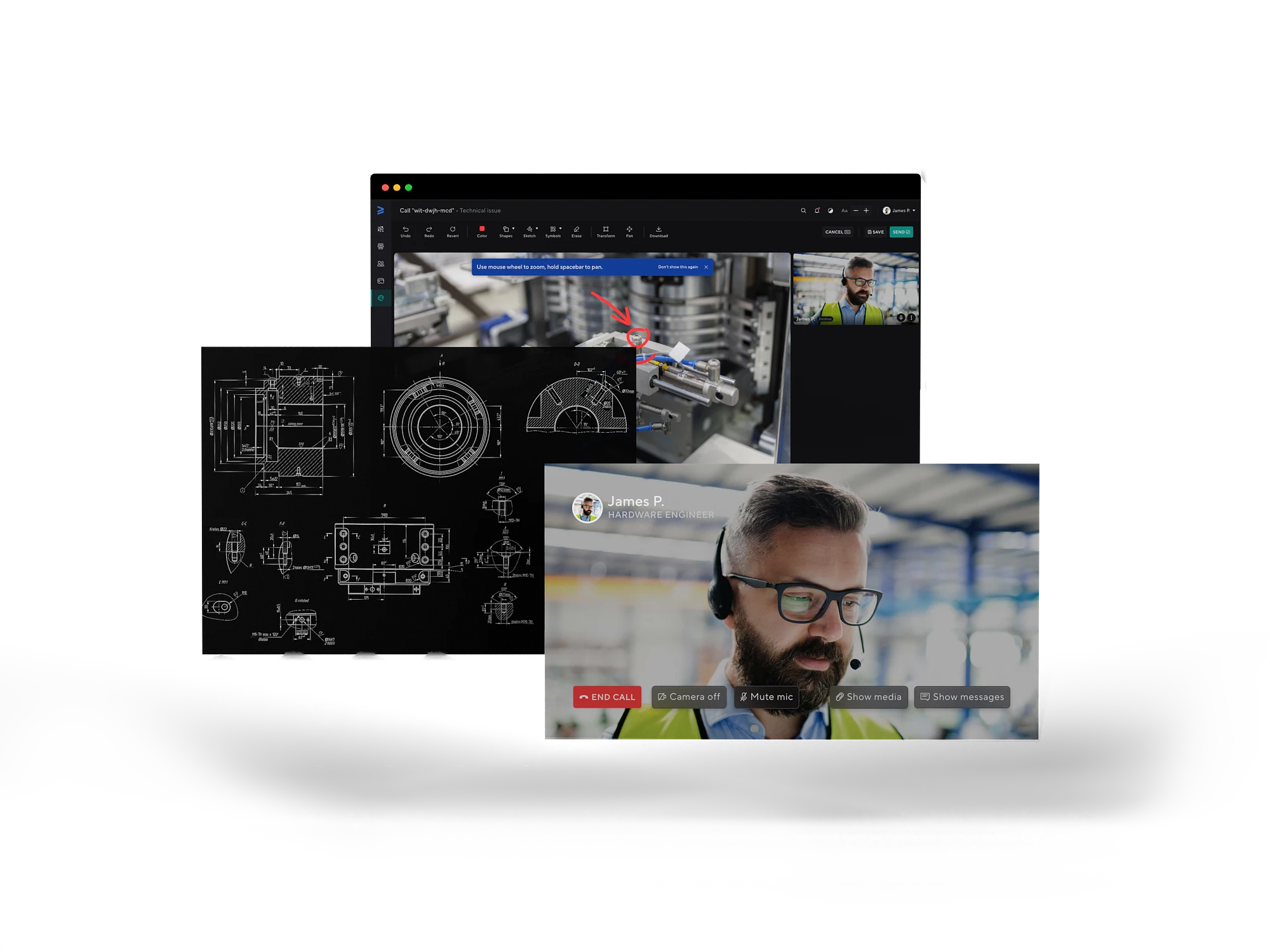

The answer to the above challenges is an AR-powered platform with its two main modules:

Unique features that will boost your efficiency

Workflow creator

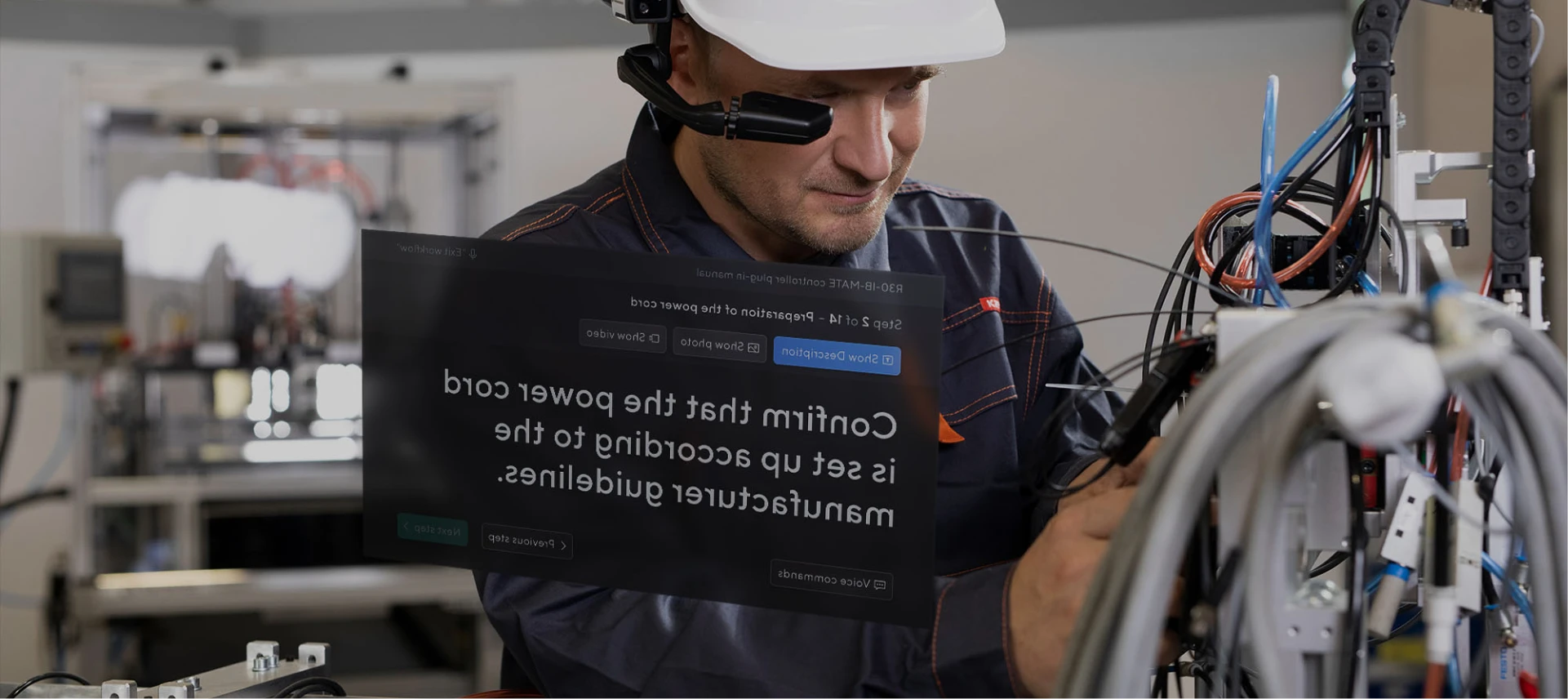

Create hands-on tutorials for machine operators and maintenance teams easily. The process is similar to playing with blocks, and requires no coding skills or specialized devices.

3D models and holograms

Replace costly physical models of machines or their components with life-like holograms. It helps in building production lines, supports new solutions prototyping and testing.

Service checklists

Create customized checklists for audit or maintenance. They will instruct on and document every step of the procedure. Data obtained this way can be used to generate protocols and reports.

Digital twins

Your staff can undergo A-to-Z training with virtual machines that look and behave like the real ones. They can display instructions on AR glasses and the system can verify task completion.

Benefits of Nsflow for automotive industry

Easy, 24/7 access

Provide your employees with constant access to information. Whether it’s onboarding, re-training, or updating on the newest guidelines, nsFlow is available when your staff need it.

Cost efficiency

Augmented reality in manufacturing allows you to cut costs of business travel, human errors, downtimes resulting from equipment malfunction, and overcome limited access to experts.

Business scalability

The platform allows you to scale any time you need it. Add new employees and train them with no extra costs. Use a remote support module to effectively use your experts’ time.

Secured know-how

Digitalize your instruction manuals and reports. Save your experts’ practical knowledge in the form of checklists, on-the-job training, and service recordings from AR glasses.

Learn more about our solution

Get a 14-day

FREE TRIAL

AR devices included, no risk and no cost involved.

See more use Cases

Nsflow solutions can be adopted in a variety of industrial scenarios to improve your business processes.

Industrial onboarding

Get your employees ready to work with step-by-step AR training, with minimal instructor engagement.

Remote FAT

Check equipment and machinery functionality and quality before they leave the production line – remotely.

Digital Workflows

Retain and standardize knowledge in your company with interactive training, instructions, and service procedures.