Defined simply, AR is the overlay of digital content on the real world, achieved using various technologies like wearables or smartphone apps. It offers a blend of the physical and digital worlds, transforming how users interact with their environment.

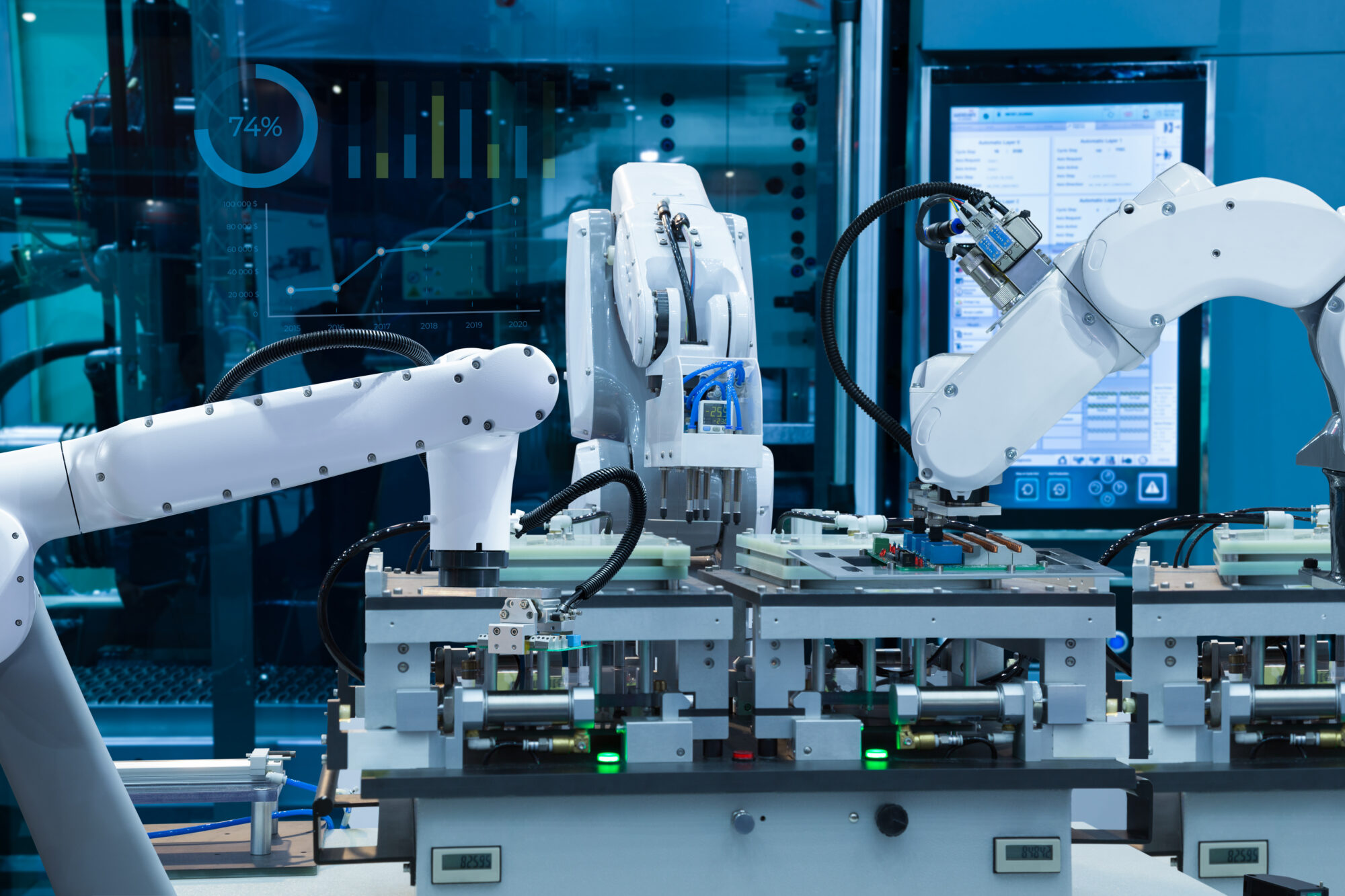

Industrial Augmented Reality, a subdomain of AR, specifically caters to the needs and challenges of industrial sectors. Whether it’s manufacturing, logistics, or product design, Industrial AR provides tools and solutions that enhance operations, streamline processes, and foster innovation. In this article, we delve deep into this transformative technology, exploring its myriad applications, benefits, challenges, and the tech that drives it.

While AR’s entertainment applications often steal the spotlight, its industrial applications have proven to be revolutionary. The profound impacts of AR on the industrial sector include improved efficiency, reduced operational costs, and elevated safety standards. As industries continually seek innovation, AR emerges as a front-runner in reshaping the industrial landscape.

The evolution of AR in industrial sectors

The connection between Augmented Reality and industry is not a recent phenomenon. In the late 20th century, industries started experimenting with computer-assisted designs and simulations. These early forays, although rudimentary, laid the foundation for the sophisticated AR applications we see today. From basic holographic projections to intricate overlay systems, the journey has been both evolutionary and revolutionary.

The 21st century saw a rapid convergence of technologies — enhanced computational power, improved graphics, and the advent of wearables. This confluence supercharged AR’s entry into various industrial sectors. Modern industries recognized the potential of AR to simplify complex tasks, provide real-time insights, and offer immersive training experiences. What began as mere experimentation soon transitioned into integral operational strategies for numerous companies.

Now, in our current era, AR isn’t just an adjunct tool but often a central component in many industrial operations. From automotive manufacturers leveraging AR for intricate assembly processes to logistics companies optimizing warehouse operations, AR’s industrial footprint is expanding at an unprecedented rate. As the technology matures, its adoption is only set to rise, reshaping industries in ways we are only beginning to grasp.

Core technologies driving industrial augmented reality

At the heart of Industrial Augmented Reality are a host of technologies that come together to create immersive and practical AR experiences. AR wearables and glasses, for instance, have undergone significant evolution. Today’s industrial AR glasses are lightweight, durable, and packed with features. They can overlay intricate data on a user’s field of vision, guiding them through complex tasks or providing real-time diagnostics.

The magic of AR is not just in visualization but also in real-time data processing. By leveraging cloud integration, AR systems can access vast data repositories, process this information, and present relevant insights instantly. This is especially crucial in industries where timely decisions can impact production schedules, quality, or safety. The integration of AR with cloud computing ensures that even the most data-intensive tasks are handled seamlessly.

Moreover, 3D modeling and visualization tools have enriched the AR experience. Industries can now create detailed simulations, prototype designs, or model solutions in three dimensions, offering a depth of understanding previously unimaginable. Complementing this is the synergy of AR with the Internet of Things (IoT). As industrial devices become smarter and interconnected, AR systems can pull data from these devices, providing a holistic view of operations and assisting in predictive maintenance, real-time monitoring, and more.

Key applications of industrial augmented reality

The beauty of Industrial AR lies in its versatility. In manufacturing, AR has emerged as a game-changer. Technicians can now access real-time machinery diagnostics, pinpointing issues or areas of concern instantly. This not only reduces downtimes but also improves overall machine efficiency. Furthermore, guided assembly processes powered by AR ensure that intricate manufacturing tasks are carried out with precision, reducing errors and enhancing product quality.

Training and skill development have also seen a paradigm shift with AR’s advent. Traditional training methods, often theoretical and detached from on-ground realities, are now being supplemented or even replaced by AR-driven training modules. These modules offer immersive environments where trainees can practice tasks, receive instant feedback, and refine their skills. This hands-on approach ensures that trainees are better prepared for real-world scenarios, reducing the learning curve significantly.

Logistics and warehousing, sectors often bogged down by inefficiencies, have found a powerful ally in AR. Inventory management, traditionally a labor-intensive task prone to errors, has been transformed with AR-driven visualization tools. Employees can now locate products, understand inventory levels, and plan routes within warehouses using AR glasses. Similarly, the design and product development realms have embraced AR for prototyping, simulations, and collaborative design reviews, ensuring that products are optimized even before they hit the production floor.

presentation to try

Nsflow in action

Benefits of augmented reality solutions in the industrial sector

The adoption of AR in industries isn’t merely driven by the allure of cutting-edge technology, but by the tangible benefits it offers. Chief among these is enhanced operational efficiency. AR applications allow industries to streamline workflows, optimize processes, and minimize downtimes. As a result, industries can achieve higher output with the same or even fewer resources, driving profitability.

Training, traditionally a time-consuming and expensive endeavor, sees significant cost reductions with AR. The interactive nature of AR-driven training modules ensures that trainees grasp concepts faster and retain them longer. Furthermore, the ability to simulate real-world scenarios without the associated risks means that training can be both comprehensive and safe, leading to better-prepared employees at a fraction of traditional training costs.

AR also plays a crucial role in elevating safety standards across industries. By offering real-time insights, AR helps operators identify potential hazards before they manifest as actual threats. Similarly, AR aids in ensuring regulatory compliance by guiding operators through standardized procedures, thereby reducing the chances of oversights and errors. This not only safeguards the workforce but also mitigates legal and financial risks associated with non-compliance.

The future of augmented reality in the industrial sector

The trajectory of AR in industries is undoubtedly upward. As AR hardware undergoes continuous improvements, its applications in industries are set to broaden. These hardware enhancements, coupled with the integration of other emerging tech like Virtual Reality (VR), promise richer and more immersive AR experiences.

Small and Medium-sized Enterprises (SMEs) stand to benefit immensely as AR tools become more accessible and affordable. This democratization of AR means that even smaller players can leverage its benefits, leveling the playing field in many sectors. Furthermore, as global supply chains become more intricate, AR can play a pivotal role in streamlining operations, ensuring that industries can respond to market dynamics swiftly and efficiently.

The overarching theme for AR’s future in industries is integration. As AR integrates with other tech, from AI to VR, its applications will multiply, ensuring that industries can harness its potential in myriad ways. Whether it’s enhancing productivity, ensuring safety, or driving innovation, AR’s future in industries is bright and boundless.

The takeaway

Industrial Augmented Reality stands at the intersection of innovation, efficiency, and transformative potential. As we’ve journeyed through its evolution, core technologies, myriad applications, and glimpsed into its promising future, one thing becomes clear: AR is not just an add-on but a fundamental shift in how industries operate, innovate, and grow.

Encouraging industries to embrace and invest in AR is more than just an endorsement of a new technology. It’s a call to prepare for a future that promises to be more interconnected, efficient, and data-driven. With AR, industries have a tool that not only solves contemporary challenges but also anticipates and addresses future hurdles. It offers a roadmap to a world where operations are streamlined, training is immersive, and decision-making is data-informed.

As we stand on the cusp of this AR-driven industrial revolution, it’s imperative to recognize that this journey is one of continuous innovation and refinement. The applications, strategies, and successes of today lay the foundation for the breakthroughs of tomorrow. Industrial Augmented Reality, with its limitless potential, beckons industries to a future that is brighter, smarter, and more sustainable.