Why is equipment maintenance important?

Scheduled and purposeful inspections help to identify potential problems and forecast necessary maintenance.

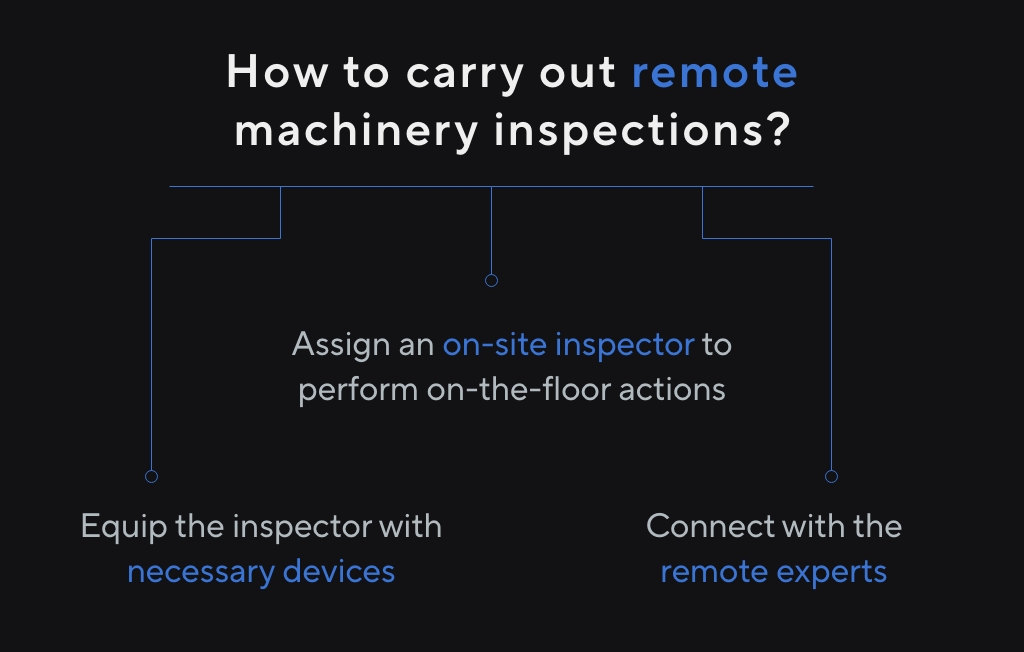

Proper functioning of machinery requires attention. Unfortunately, the watchful eye of inspectors can’t always overview the operations in person. Various challenges, e.g. pandemic-related travel restrictions, limited availability of experts, and large distances between plants, can disrupt the inspection process. To ensure operational continuity and banish the specter of unnecessary costs caused by unattended machinery, industrial companies may benefit from the support offered by augmented reality.

Sounds pretty easy, and really is easy

To shed some more light on the processes, let’s dive deeper into the remote inspections.

Checklists

Preparing for the process, plan a machinery inspection checklist. A well-prepared document helps assure that each required area is covered, each element verified, and each process assessed. Checklists leave no piece unattended – ticking each piece off helps to avoid omitting equipment and components in question. The easiest way to ensure meticulous control is to move the service documents to the AR platform. As a result, technicians carrying out inspections won’t omit any step on the checklist.

The equipment

The remote inspection itself is carried out by an on-site employee, usually equipped with an AR wearable device (or, in some cases, a smartphone or tablet, depending on the needs and requirements), staying in touch with the expert located elsewhere. One approaches the inspected machinery and, using the AR platform, provides the other with real-time footage of the machine’s functioning.

The person responsible for assessing the machinery operations and its condition doesn’t need to use a dedicated AR device. Remote experts are perfectly fine using their tablets or computers to display the videos and images shared by on-site inspectors.

From our experience, smartphones and tablets can successfully be used in such operations, as long as the process itself doesn’t entail actions performed by the inspector using both hands. In case the inspection requires numerous activities, wearable equipment will be a better choice. AR glasses can be fully voice and gesture-controlled, leaving operators’ hands free to perform the necessary actions arising from machine operations.

Choosing the best-suited AR device is related to the actual needs of the plant. Depending on the industrial environment your company operates in, various AR devices may suit your needs best. While for indoor procedures in moderate conditions the Microsoft HoloLens 2 should be sufficient, in the most demanding surroundings, the best choice will be the RealWear Navigator 500.

The platform

One of the core built-in modules of the Nsflow platform, Remote Support, has been designed with operations like remote inspections in mind. The AR-powered solution is the closest to an in-person experience one can achieve. What’s even better is that the setup is easy and doesn’t require additional software or advanced coding skills. On-site personnel needs to launch the AR device and share a link to the consultation meeting.

The process

From that point on, the real-time connection is established and the magic happens. The person inspecting the machine (either equipped with a wearable device or holding a portable piece) is operating on-site. The actions include running the machine in the standard mode and assessing its behavior under emergency conditions.

The recipient (remote expert) sees machinery operation and can report abnormalities, annotate the displayed images and videos, and save notes for further processing (reports, instructions). To fully comprehend the machine’s operation, the recipient will ask the on-site technician to point the built-in camera to areas requiring attention and investigate details. Data gathered during the remote inspections can be used to automatically generate reports compliant with prepared in advance templates. Automatic reporting saves time usually spent on manually completing tables and compiling data. Generated reports can be supplemented with advised corrective actions and maintenance guides to ensure optimal future operations of the machine.

Since augmented reality enables the assessment of machinery prior to implementation in the target workspace and early production stages, its potential became a pillar of remote Factory Acceptance Tests (FAT).

presentation to try

Nsflow in action

In short

Effective execution of remote machinery inspection calls for an on-site technician equipped with an augmented reality device, an open session to communicate with them, and their access to the machines in question. The rest is on the expert/inspector/auditor side – asking for actions to perform, tasks to complete, and flagging elements to devote special attention to. Everything can be recorded and automatically documented, omitting the need for manually created inspection reports.

Powered by AR, remote inspections are a great chance for industrial enterprises to cut unnecessary costs and maintain efficient operations in distant locations, also in the post-pandemic world.

Not sure if you already have answers to all your questions about remote machinery inspections? We’re here to help – let us know what’s on your mind. Or even better – try out the Nsflow demo to see how augmented reality will change machinery inspections for the better.

And if you’d like to read more about how AR helps improve industrial processes, get your free copy of our ebook.