Quality control solutions

Utilize the watchful eye of AR to ensure the highest quality in industrial operations

Quality control solutions

End-to-end quality control entails meticulous attention, precision, and an eye for detail. Employ AR to achieve excellence in your operations.

Get to know more

Ensuring compliance

Unambiguous conformity with norms, standards, legal requirements and other regulations is vital to launch a product and maintain its position on the market. The more advanced the item or the more demanding the market, the greater challenge it is to perform quality control faultlessly.

Testing, testing, testing

Equip your quality control team with the most precise tool, allowing them to shadow performed operations, supervise the process, and assess the final product to ensure its excellence.

Facing a lack of understanding of the product

No matter where the product is assembled or whether the on-site personnel is accustomed to its specifics (e.g., offshore production of items popular on the other side of the globe), the final results must comply with top-down standards.

Challenges

Businesses carry out diverse operations, yet they all have a common denominator. It is the need for securing all stages of development to deliver comprehensive, working products that not only meet but exceed expectations.

Documentation management

Industrial processes generate extensive documentation, which often requires further updates and amendments. Keeping up to date with the ever-growing resource burdens quality controllers with additional work.

Human error

Fatigue, inattention, distraction, and external factors are likely to affect human perception. In a technologically advanced environment, relying solely on individual memory and experience is frequently not enough to deliver satisfactory results.

Process efficiency

Maintaining an equal level of quality assurance across your facilities and products depends on access to standardized resources and competencies. Eliminate external factors endangering quality control in your organization.

Distance

Quality control professionals work at various locations, remaining in touch with their affiliates, and cooperating in real-time on cases requiring consultations.

What troubles your company?

We will be happy to discuss your needs and possible solutions.

The solution

Impeccable precision can be ensured through AR applications:

A broad selection of features for quality control professionals

3D MODELS AND HOLOGRAMS

Use Nsflow to visualize the inspected objects with 1:1 digital imagery, mimicking the way a real-life machine or product appears and behaves. Create digital twins to assess the controlled items without halting production or operation.

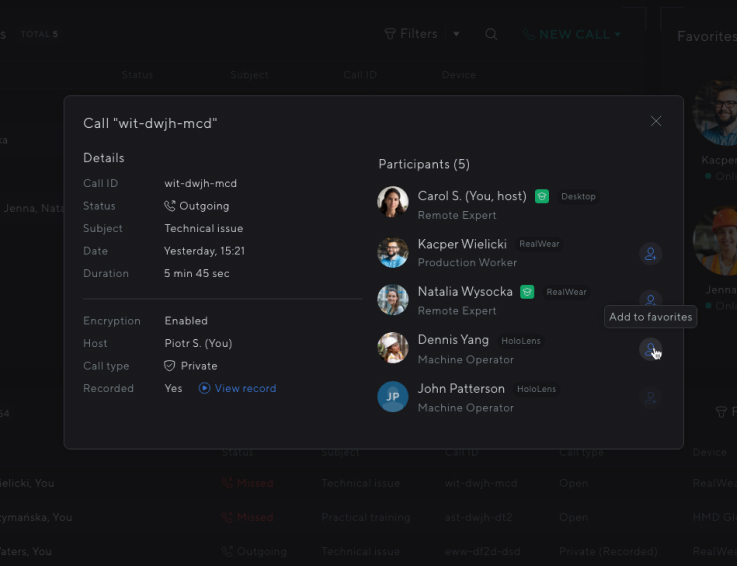

DETAILED REPORTING

Operations carried out are live-streamed on the admin panel’s dashboard. Supervisors can track the progress of quality control procedures and draw data-based conclusions. Reports are automatically saved in convenient formats.

INTEGRATION WITH SCADA, MES, ERP, CRM, AND PLM SYSTEMS

For maximum accuracy and high performance of quality control duties, Nsflow enables integration with internal systems, enabling remote machinery inspection, maintenance, and data exchange.

CHECKLISTS

Thanks to digital checklists designed to assess products, services, and processes, you will never overlook a detail in your work. With Nsflow, every team member is aligned with others, working in accordance with relevant documents.

AR benefits professionals by ensuring industry quality on an industry-wide level

DATA MANAGEMENT

Nsflow enables data and reports aggregation all in one place, for convenient oversight of quality control operations. Assessment of data facilitates fast conclusion drawing, which contributes to the elimination of quality declines.

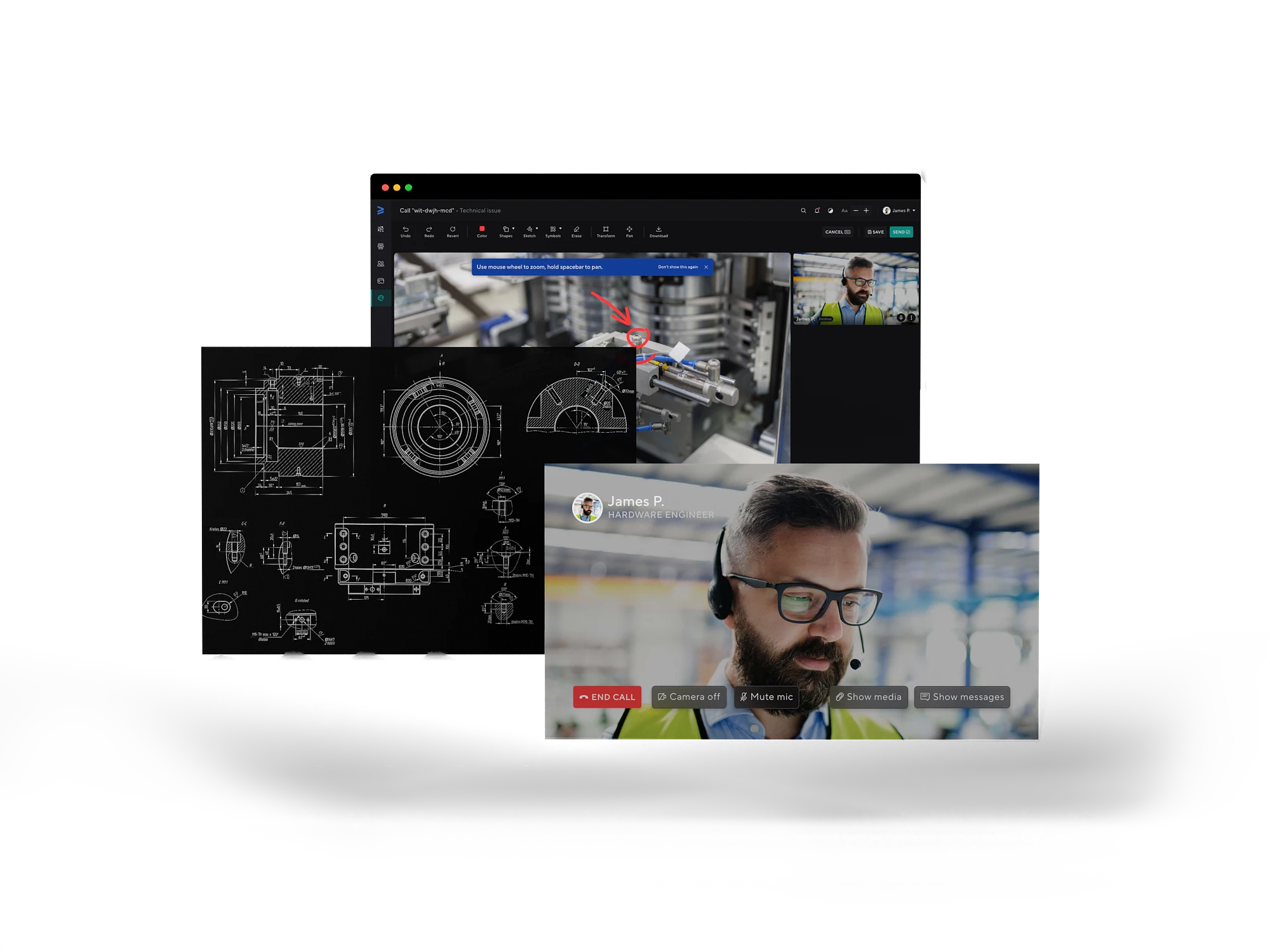

REAL-TIME COMMUNICATION

The AR platform supports efficient communication between professionals working on-site and their co-workers in other locations. Audio, video, transmitting and receiving information – everything that’s required to carry out processes.

EXPERTISE STANDARDIZATION

Company-wide standards and their even execution can be achieved by adopting the AR tool that aggregates knowledge, procedures, and regulations. As a result, quality control experts are always on the same page with the possibility of swiftly updating the whole library.

COST AND TIME OPTIMIZATION

Boosting quality control processes leads to better and safer products and processes. In addition, AR helps reduce downtimes and malfunctions, and its role in eliminating human error is not to be underestimated.

Learn more about our solution

Get a free 14-day trial*

*AR devices included, no risk and cost involved